Install Instructions

18

EMP

Installation & Service Manual

109529-03 - 11/19

A. EVALUATE THE EXISTING WATER

SYSTEM.

Design a piping system and install boiler which

will prevent oxygen contamination of boiler water

and frequent water additions.

1. There are many possible causes of oxygen

contamination such as:

a. Addition of excessive make-up water as a

result of system leaks.

b. Absorption through open tanks and fittings.

c. Oxygen permeable materials in the

distribution system.

2. In order to insure long product life, oxygen

sources must be eliminated. This can

be accomplished by taking the following

measures:

a. Repairing system leaks to eliminate the

need for addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fittings which

allow oxygen absorption.

d. Use of non-permeable materials in the

distribution system.

e. Isolating the boiler from the system water by

installing a heat exchanger.

WARNING

System supply and return piping must be

connected to correct boiler manifolds.

U. S. Boiler Company recommends sizing the

system circulator to supply sufficient flow (GPM)

to allow a 20°F temperature differential in the

system. When sizing the system circulator, the

most restrictive single zone should be used to

determine maximum pressure drop.

CAUTION

Maintain minimum ½ inch clearance from hot

water piping to combustible materials.

3. In order to insure long product life, operate boiler

at appropriate flow rate to minimize areas of

overheating

.

a. Design system to ensure that the flow is above

the limit called for in Table 5.

b. Maintain a constant boiler pressure of 12 PSI.

WARNING

Do not operate boiler below minimum volumetric

flow rates.

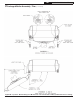

B. CONNECT SYSTEM SUPPLY AND RETURN

PIPING TO BOILER. See Figures 9A and 9B.

Also, consult I=B=R Installation and Piping Guides.

1

. If boiler is used with an Alliance™ SL Indirect Fired

Domestic Water Heater, install the Alliance™ SL as

a seperate heating zone. Refer to the Allaince™ SL

Installation, Operating, and Service Instructions,

for additional information.

2.

The EMP is designed to withstand thermal shock

from return water temperatures as low as 100ºF,

but prolonged return temperatures of below 135ºF

can cause excessive flue gas condensation and

damage the boiler and/or venting system.

Use a boiler bypass if the boiler is to be operated

in a system which has a large volume or excessive

radiation where low boiler water temperatures

may be encountered (i.e. converted gravity

circulation system, etc.) The bypass should be

the same size as the supply and return lines

with valves located in the bypass and return

line as illustrated in Figures 9A and 9B in order

to regulate water flow for maintenance of higher

boiler water temperature.

3. If it is required to perform a long term pressure

test to the hydronic system, the boiler should

first be isolated to avoid pressure loss due to the

escape of trapped air.

To perform a long term pressure test including

the boiler, ALL trapped air must first be removed

from the boiler.

A loss of pressure during such a test, with no

visible water leakage, is an indication that the

boiler contained trapped air.

Boiler Model No. Flow Rate (Gal / Min)

EMP84E 4.5

EMP115E 4.5

EMP140E 8.0

EMP182E 10.0

EMP224E 12.0

Table 4: Minimum Flow Rate

3 Water Boiler Piping

NOTICE: Failure to pipe boiler as specified in this

manual may result in excessive system noise.

!

!

!