Install Instructions

15

EMP

Installation & Service Manual

109529-03 - 11/19

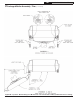

Figure 6: Piping Arrangement for Drain Valve and Indirect Water Heating Return

Step c. Pipe discharge of relief valve as

shown in Figures 9A and 9B. Installation

of the relief valve must be consistent

with ANSI/ASME Boiler and Pressure

Vessel Code, Section IV.

WARNING

Safety valve discharge piping must be piped

near floor to eliminate potential of severe burns.

Do not pipe in any area where freezing could

occur. Do not install any shut-off valves, plugs

or caps.

2. Install drain valve and indirect water heater

return piping, see Figure 6.

Step a. Apply pipe sealant to both ends of

1-1/4" NPT x 5" lg. nipple. Thread nipple

into 1-1/4" NPT lower rear tapping on rear

section.

Step b. Thread 1-1/4" x 1-1/4" x 3/4" NPT tee

on opposite end of 5" lg. nipple installed in

Step a.

NOTE: Based on access for servicing

and location of sewer or floor drain, when

tightening these fittings, determine if drain

valve is to be located on the left or right

side.

Tighten nipple and tee into 1-1/4" NPT lower

rear tapping or rear section until joints are

water tight for desired position.

Step c. Apply sealant to 3/4" NPT thread on

drain valve. Thread into 3/4" NPT tapping

on side outlet of tee. Use hex nut portion to

tighten valve until water tight.

Step d. If an Alliance™ SL water heater is

connected to system, do not install 1-1/4"

NPT pipe plug. Connect piping as shown in

Figures 9A and 9B, as applicable. Also refer

to Alliance™ SL instructions for additional

information.

3. Installing stainless steel flueway baffles. Baffle

requirements differ from model to model, see

Table 3.

NOTE: Read caution statement before proceeding.

Step a. Install stainless steel baffles provided

in miscellaneous parts carton as follows,

refer to Table 3 and Figure 7:

2 Packaged Boiler Assembly - Trim (continued)

!