System information

18-BC53D2-6 23

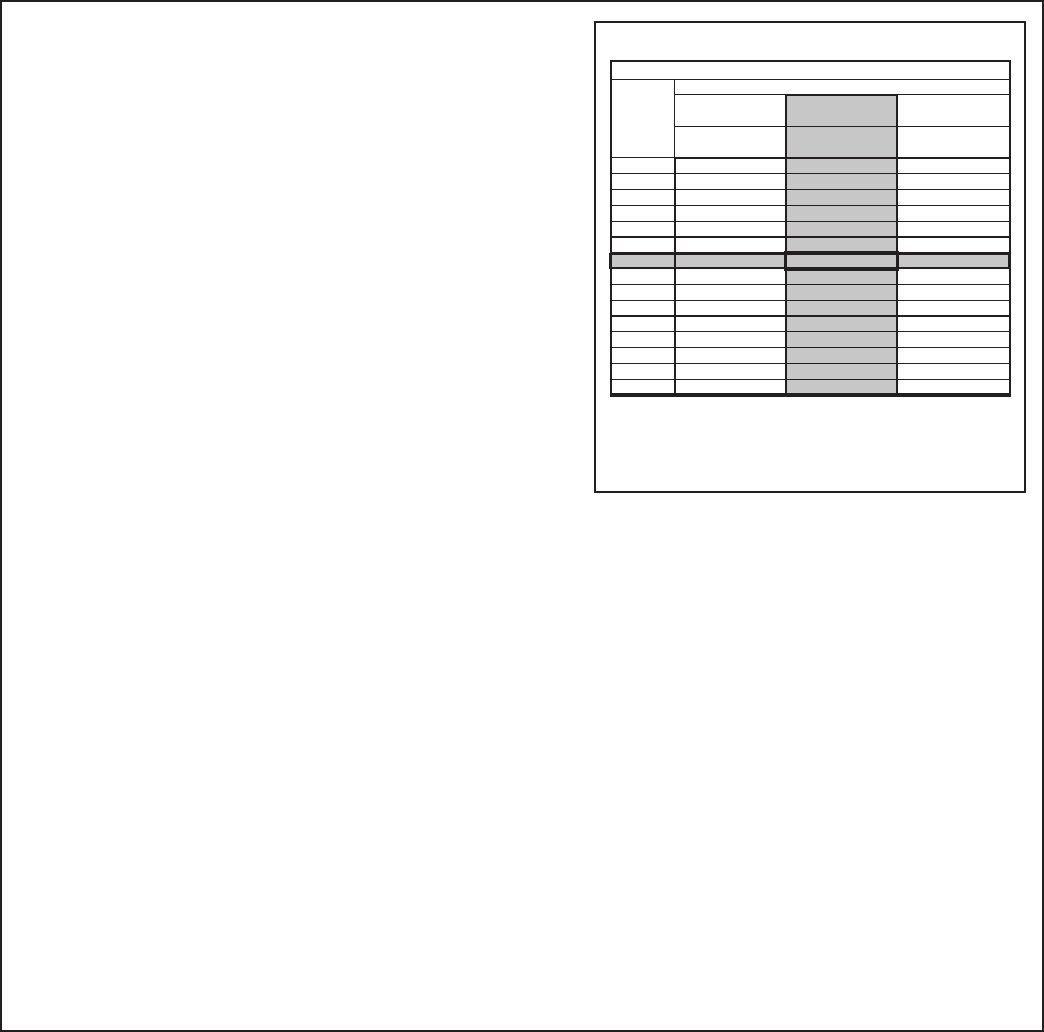

Example

Use the liquid line temperature and liquid line

gage pressure from Step 2, along with the Dip

Switch setting column, to determine the proper

Liquid Gage Pressure.

STEP 3 - Find the appropriate refrigerant charg-

ing chart on the following page for your system

type and tonnage.

STEP 4 - Locate your liquid line temperature in

the left column of the table and the intersecting

liquid line gage pressure under the DIPSWITCH

selection column.

Example:

• A 3 ton AC is installed with line length of 30

feet and a line lift of 15 feet.

• The Dip Switch setting is 2-ON.

• The measured liquid line temperature is

85°F and the Liquid Gage Pressure is 299

PSIG.

299 PSIG is shown as the intersection of the

Dip Switch ON column and the 85°F Liquid

Temperature row.

ONLY DIPSWITCH

1 ON

ONLY DIPSWITCH

2 ON

ONLY DIPSWITCH

3 ON

LOWER * MIDDLE UPPER

55 186 186 190

60 202 202 206

65 219 219 222

70 237 237 240

75 256 256 260

80 277 277 280

85 299 299 302

90 322 322 325

95 346 346 350

100 371 371 375

105 397 397 402

110 425 425 430

115 454 454 460

120 484 484 491

125 515 515 523

PRINTED FROM D155861P02 REV 2

Liquid

Tem

p

(

°F

)

LIQUID GAGE PRESSURE (PSIG)

3 TON AC R410A REFRIGERANT CHARGING CHART

* Data is based on 10.5° of subcooling at a 95° ambient