Install Instructions

14

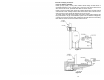

Oil tanks and Piping Continued-

Fuel supply LEVEL with or ABOVE burner

The burner may be equipped with a single-stage fuel unit for these installations.

Connect the fuel supply to the burner with a single supply line if you want a 1-

pipe system (making sure the bypass plug is NOT installed in the fuel unit).

Manual bleeding of the fuel unit is required on initial start-up. If connecting a 2-

pipe fuel supply, install the fuel unit bypass plug.

Fuel supply BELOW the level of the burner

When the fuel supply is more than (8) feet below the level of the burner, a 2-pipe

fuel supply system is required. Depending on the fuel line diameter and horizontal

and vertical length, the installation may also require a 2-stage pump. Consult the

fuel unit manufacturer’s literature, included with the burner, for lift and vacuum

capability.

Fuel line installation

Continuous lengths of heavy wall copper tubing are recommended. Always use

flare fittings. Never use compression fittings.

Always install fittings in accessible locations. Proper routing of fuel lines is

required to prevent air cavitation and vibration.

WARNING

DO NOT install by-pass plug with 1-pipe system. Failure to comply

could cause immediate pump seal failure, pressurized oil leakage and

the potential for a fire and injury hazard. The burner is shipped without

the by-pass plug installed. Install the by-pass plug in 2-pipe oil supply

systems ONLY.

CAUTION

Oil supply pressure control is required. Damage to the filter or pump

seals could cause oil leakage and a fire hazard. The oil supply inlet

pressure to the burner CANNOT exceed 3 psi. Insure that a pressure

limiting device is installed in accordance with the latest edition of NFPA

31.

DO NOT install valves in the return line (refer to NFPA 31).

For gravity feed systems, always install an anti-siphon valve in the oil

supply line or a solenoid valve in the pump/nozzle discharge tubing to

provide backup oil flow cut-off protection.