Installation / Operation Instruction Manual

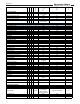

Table Of Contents

- Cover

- TABLE OF CONTENTS

- General Information

- SECTION 2 Venting and Combustion Air

- SECTION 3 Gas supply and Piping

- SECTION 4 Water Flow and Headloss Data

- SECTION 5 Boiler Piping

- SECTION 6 Condensate Drain Trap

- SECTION 7 Electrical Connections

- 7.A Installation Warnings

- 7.B Main Power Connections

- 7.C Main Power Data

- 7.D Control Panel Layout

- 7.E Field Connections

- 7.E.1 Power

- 7.E.2 Dry Contacts

- 7.E.3 Temperature Sensors

- 7.E.4 Safety Chain

- 7.E.5 Isolation Valve

- 7.E.6 Heat Demands

- 7.E.7 Analog In and Analog Out

- 7.E.8 Dry Contacts. Run & Alarm

- 7.E.9 RS 485 for Cascade (Lead Lag)

- 7.E.10 RS485 BMS

- 7.F Modbus to BACnet Memory Map (4 pages)

- 7.G WiringDiagram

- 7.H High Voltage Wiring Diagrams (5 pages)

- 7.I Ladder Diagrams (8 pages)

- SECTION 8 Control Operation

- 8.A The Home Screen

- 8.B Login to Lock / Unlock the Display Screen

- 8.C Quick Start

- 8.D Configuration

- 8.E Service Screens

- 8.E.1 Burner

- 8.E.2 Digital I/O ( Input / Output )

- 8.E.3 Analog I/O

- 8.E.4 Screen Settings Timeout

- 8.E.5 History

- 8.E.6 Restart Touchscreen & Recalibrate

- 8.E.7 Factory Reset

- 8.E.8 HMI Model OEM only

- 8.E.9 BIC Model OEM only

- 8.E.10 Both Model. OEM only.

- 8.E.11 About (the Firmware)

- 8.E.12 O2 (Trim Set Point)

- 8.E.13 LMV

- 8.F Messages and USB

- 8.G Active Demands

- SECTION 9 Parameter Tables (3 pages)

- SECTION 10 Initial startupInstructions

- SECTION 11 Maintenance

- SECTION 12 Troubleshooting

- SECTION 13 Replacement Parts

- 13.A Frame and Jacket Assembly, Part Numbers

- 13.B Control Panel Assembly, Part Numbers

- 13.C Blower and Burner Assembly,Part Numbers. ALL Sizes

- 13.D AC Distribution Box Assemblies and Part Numbers

- 13.E Burner Door Part Numbers

- 13.F Waterway Inlet Assembly, Part Numbers

- 13.G Waterway Outlet Assembly, Part Numbers

- 13.H Gas Train Part Numbers

- 13.I Exhaust Manifold Part Numbers

Page 109

10.B Initial Operation

The initial setup must be checked before the unit is

put into operation. Problems such as failure to start,

rough ignition, strong exhaust odors, etc. can be due

to improper setup. Damage to the boiler resulting from

improper setup is not covered by the limited warranty.

10.B.1 Initial Burner Operation

1. Using this manual, make sure the installation is

complete and in full compliance with the instructions and

all local codes.

2. Determine that the unit and system are lled with

water and all air has been bled from both. Open all

valves.

3. Observe all warnings on the Operating Instructions

label and turn on gas and electrical power to the

unit. It may be neccesary to reset the low pressure

switch.

4. The unit will enter the start sequence. The blower

and pump will energize for pre-purge, then the

ignition sequence will start. After all safety devices

are veried, the gas valve will open.

If ignition doesn’t occur, turn o the unit. Check

that there is proper supply of gas. Wait ve

minutes and start the unit again.

5. If ignition starts normally, leave the unit turned on.

6. After placing the unit into operation, the burner

safety shuto device must be tested:

(a) Close the gas shuto valve with the burner

operating.

(b) The ame will go out, and the blower will continue

to run for the post purge cycle. A few additional

attempts to light will follow including pre-purge,

ignitor on, valve/ame on and post purge. Ignition

will not occur because the gas is turned o. The

ignition control will lockout.

(c) Open the gas shuto valve. Reset the boiler

control by pressing the Reset button on the

control. Restart the unit. The ignition sequence will

start again and the burner will start. The unit will

return to its previous mode of operation.

WARNING

If any odor of gas is detected, or if the gas burner

does not appear to be functioning in a normal

manner, close the main gas shuto valve. Do

not shut o the power switch. Contact your heating

contractor, gas company, or factory representative.

WARNING

Do not use automotive antifreeze. To help prevent

freezing, the manufacturer recommends the use of

inhibited propylene glycol. See 5.C on page 26

WARNING

Improper adjustment may lead to poor combustion

quality, increasing the amount of carbon monoxide

produced. Excess carbon monoxide levels may lead

to personal injury or death.