Operator`s manual

Page 19

MANUAL ASPIRATOR PUMP

GENERAL: The manual aspirator option is an inexpensive method of adding remote

sampling capabilities to a BW DEFENDER . The Aspirator Pump and Sampling Hose

are joined by a simple quick connect. The D4-AS01 Aspirator Pump is equipped with

the squeeze bulb and an in-line water trap (Order #: D4-WT-1) When ordered, the

D4-AS01 includes a D4-HAS-10 10 ft. (3.1m) sampling hose (longer lengths

available). The Sampling Hose is equipped with a Particulate Filter

(Order #: D4-PF-1).

To operate the Aspirator pump:

1. Attach the Sampling Hose (or Sampling

Probe) quick connect to the in-line water

trap on the Aspirator Pump. Turn right to

lock them together.

2. Attach the outlet hose on the bulb to the

barb connector on the calibration cap.

3. Fit the calibration cap overtop of an

operating BW DEFENDER unit.

4. Squeeze the bulb rapidly to draw sampled

gases into the BW DEFENDER.

Note 1: Keep hoses clean and dry. Clean out clogged tubing by blowing or flushing

with clean water. Allow to dry before use. Both the in-line water filter and

Particulate filters are replaceable.

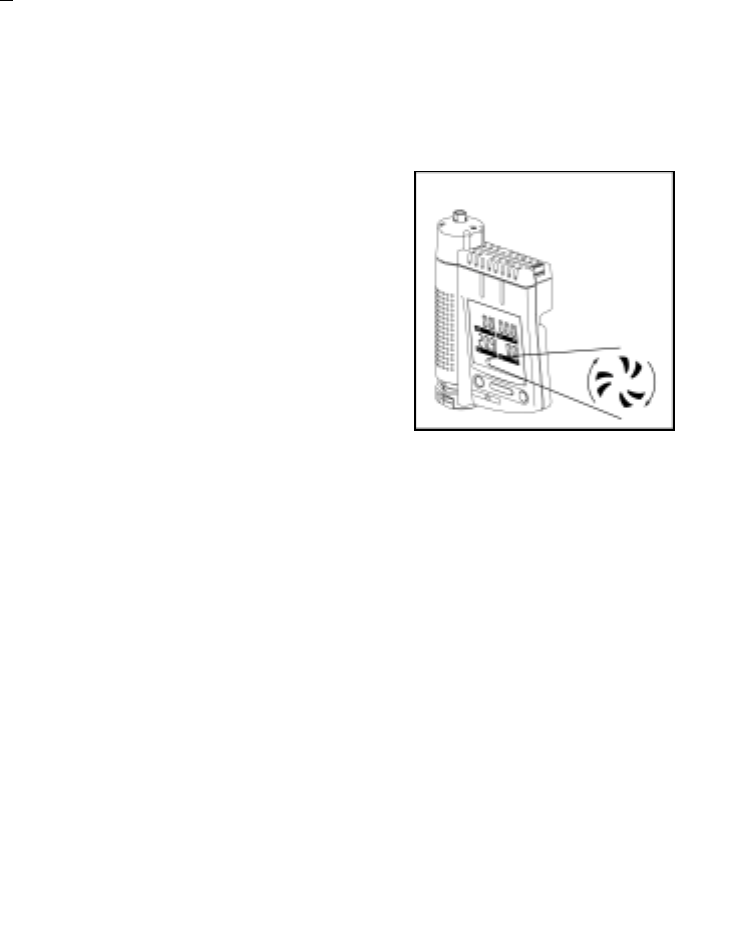

MOTORIZED SAMPLING PUMP

CONVENIENCE: A BW DEFENDER equipped with motorized Pump and allows you

to monitor in either Active Motorized Sample Mode or Ambient Diffusion Mode simply

at the flick of the switch. The integral pump is never removed during either Active or

Ambient Modes of operation.

RELIABILITY: The high efficiency

rotary vane pumps act like a small

turbine. BW DEFENDER pumps

provide better reliability and less friction

that result in lower maintenance. The

BW DEFENDER pump is not pressure

sensitive.

POWER: The Sampling Pump is

powered by the BW DEFENDER. Eight

hours of operation is expected.

SAMPLING PUMP INSTALLATION: The BW DEFENDER Sampling Pump, is

installed at the factory if ordered together. The pump can be field installed if ordered

separately.

1. Remove the 4 machine screws on the BW DEFENDER’s sensor endcap and

remove the cap sensor screens. The pump is equipped with sensor screens.

2. Fit the pump unit on the BW DEFENDER in place of the missing endcap.

3. Using 4 machine screws (provided with the pump), attach the pump unit to the

BW DEFENDER. Secure firmly in place.

Note: Overtightening screws results in the Pump Slider Switch being stiff.

19 16