Specifications

Preventive Maintenance Front Axle and Suspension

Medium Duty

(R05/09) Y53-6008A – 241 –

• Thoroughly clean hubs and bearings with solvent and a

stiff bristle brush, then dry and inspect components for

wear or damage. Re-lubricate with approved axle lubri-

cant.

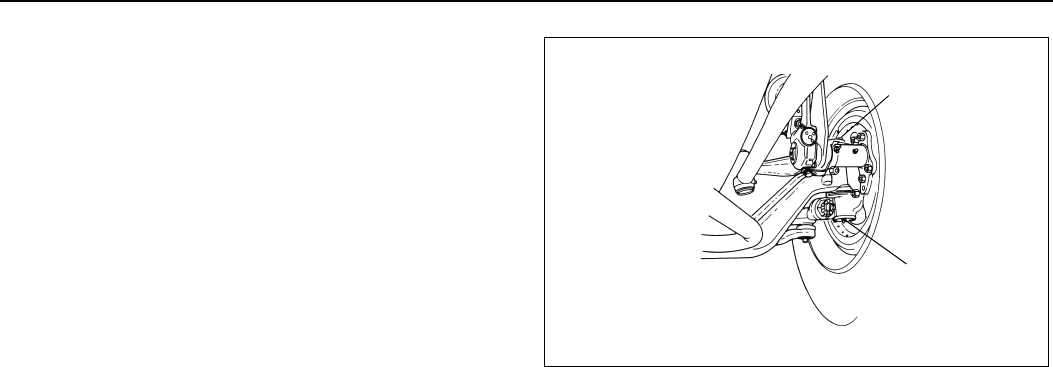

Kingpin Lubrication

• Lubricate with approved lubricant. Lubricate knuckle

thrust bearings, knuckle pins, and tie rod ends. See

Table 1, “Recommended Maintenance Intervals,”

Page 150

. Lack of lubrication causes premature wear

and hard steering. Lubrication schedule may be short-

ened if necessary.

Suspension Lubrication

Each spring anchor pin has a grease fitting. Pressure lubri-

cate spring pins according to

Table 1, “Recommended

Maintenance Intervals,” Page 150

, using EP chassis lube

with 12-Hydroxy Lithium Stearate Base NLGI-2 with 3%

molybdenum additive (e.g. Mobil-grease EP or equal).

• At regular intervals, the spring leaves may be lubricated

with a rust-inhibiting oil applied with a spray gun or

brush.

• Lubricate all spring pins until grease flows out of both

ends of the bushing. Look for signs of rust or water in the

flushed grease. If a pin will not accept grease, it should

be removed, cleaned, and inspected.

Front Axle

KINGPIN (TOP)

KINGPIN

(BOTTOM)

00445