Replacement Parts List

71

HS-300D-PL

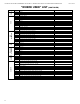

TROUBLESHOOTING HYDRONIC SYSTEM PROBLEMS

(CONT.)

VALVE SYSTEM TROUBLE ANALYSIS GUIDE

COMPLAINT POSSIBLE CAUSE RECOMMENDED ACTION

No circulation

Relief valve opens

Valve drips

Set screw not tight, coupler loose on shaft

Defective relief valve

Compression tank undersized

Waterlogged compression tank

Run-away burner

Fuel valve stuck in open position

Pump not operating

High limit control fails

Defective reducing valve

System operating pressure too high

Dirt on seal

Tighten set screw in shaft recess

Replace

Check for proper size - replace

Install air control system or drain tank

Check controls

Check valve

Check pump

Check control

Clean or replace

Check static pressure and temperature operation

Lift handle rapidly to discharge dirt - still drips - replace

Reducing valve failures

Reducing valve does not

reduce pressure

Relief valve pops - hot or

cold

Valve does not feed

Strainer plugged

Valve seat scaled shut

City pressure too high for valve

Reducing valve sticking in open position

Check if valve is scaled

Clean or replace

Turn adjustment screw all the way down to free - if it doesn’t - replace

Check valve limitation and replace with higher pressure-rated valve.

Check valve, replace if necessary

Flo-control valve

problems-

Gravity circulation

Pulsating action

Zone valves will not

operate (see note below)

Dirt on seat

Stem not turned down all the way

Valve body not installed in a horizontal position

Air in upper part of valve body

Thermostat not working properly

Power pill burned out

Sticking seal assembly valve will not seal

Take cover off and wipe seat

Turn handle on stem all the way and seat

If in a vertical position, change to horizontal, use straight or angle valve

Open cover and vent

Check thermostat

Check & replace - check electrical connections

Check and clean stem and seat for build-up of mineral scale

Note: If valve does not operate, install in a manual full open or partial position to prevent freeze-up.

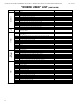

MISCELLANEOUS SYSTEM PROBLEMS

COMPLAINT POSSIBLE CAUSE RECOMMENDED ACTION

Insufficient heat in one or

more zones

Air binding

Clogged zone piping

Defective zone valve

Unbalanced circuits

Undersized radiation

Broken coupler on pump

Motor burn-out

Power off

Install air control

Locate and remove obstruction

Repair or replace

Balance

Add radiation or more insulation - increase water temperature

Check alignment of shafts - replace sagging motor mounts

Check pump motor

Check electrical connections - power source

Overheating - cold or

mild weather

Gravity circulation

Defective flo-control valve

Zone valve stuck in open position

Thermostat not operating

Flo-control valve stem in open position

Fuel valve stuck in open position

Controls not operating properly

Install flo-control valve

Clean or repair or replace

Check - repair or replace

Check - replace

Close valve

Check - replace if needed

Check

Pounding or

waterhammer

Lack of system pressure

Over-sized compression tank

Excessive boiler temperature

Pumping into the boiler using high head pumps

Use of solenoid valves

Check if static pressure is correct for system

See note below

Check to see if water is circulating through boiler - stuck fuel valve

(1)

Increase static pressure above pump head if possible.

(2)

Move pump to pump away from boiler and discharge into system.

Do not use on hydronic systems.

Crackling sound Boiler full of lime (mineral compounds) Clean and flush

Note: If a compression tank is so large that system pressure does not build-up in the proper range with temperature increase, boiling may occur in piping or radiation at the

high point of the system, particularly when pumping into the boiler.

For additional hydronic system troubleshooting information, contact your local Bell & Gossett Representative.