Owner's manual

MHM5

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@beisensors.com

INTERBUS ABSOLUTE MULTI-TURN ENCODER, MHM506-INTB RANGE

ELECTRICAL DATA

Interface Line-driver RS485 Step Frequency LSB Max 800 kHz (valid code)

Transmission rate 500kBaud or 2MBaud Accuracy + ½ LSB

Power supply 10 – 30Vdc EMC EN 61000-6-4 EN 61000-6-2

Current consumption max 3.5Watt Electrical lifetime > 10

5

h

PROGRAMMABLE PARAMETERS

The Interbus encoder supports the programmable encoder profiles K1, K2 or K3 of the ENCOM (User group of encoder

manufacturers in the Interbus club). The following parameters can be programmed directly via the INTERBUS network without any

extra devices:

Code sequence

As an operating parameter the code sequence (complement) can be programmed. This

parameter determines whether the output code increases or decreases when the axis is turned

clockwise.

Output steps over number of

revolutions

This parameter defines the number of measuring steps over the number of revolutions described

below.

Number of revolutions

This parameter determines the number of revolutions used to calculate the steps per revolution. For

example: Total resolution=8, Revolutions=2, then the Steps per revolution will be equal to 4. This

value must always be less than the total allowed revolutions (for a multi-turn, 4,096).

Preset value

The preset value is the desired output value for the actual position of the axis. The actual output

value will be set to this preset value.

Zero point displacement

This parameter sets the zero point of the output in relation to the physical zero point position of the

encoder. (same functionality as preset value).

Velocity (Optional)

Optionally, the current rotational velocity of the axis can be output in revolutions per minute.

Read-out parameter values

and temperature (Optional)

Optional all parameter values, certain other information (specified in the manual) and the

temperature value of an additional temperature sensor can be read out via the bus.

Cam functions

Cam functions which are entirely programmable via the bus are integrated in the encoder.

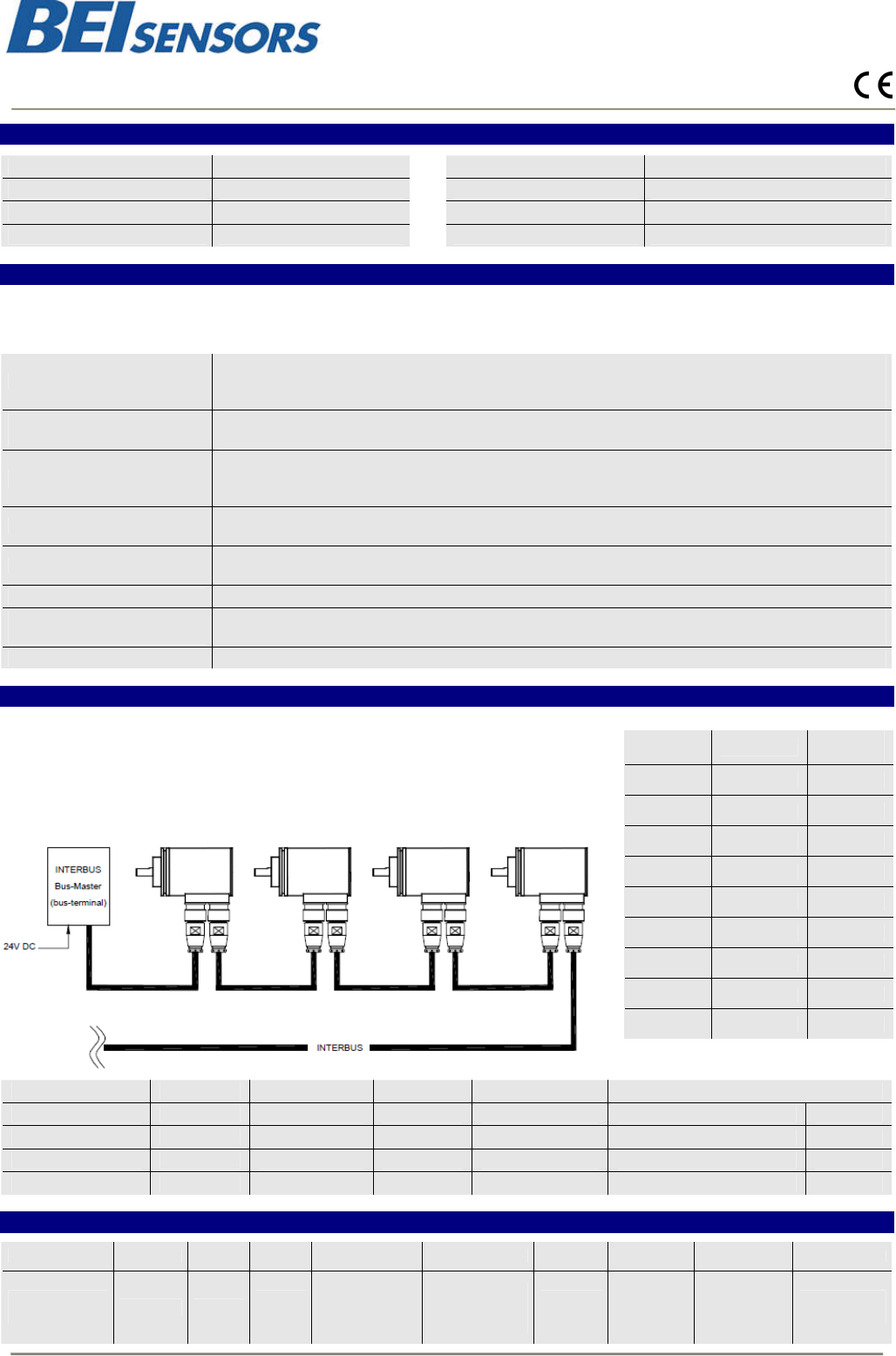

INTERFACE

The rotary encoder is connected by two cables via 9-pin connectors, one as input line,

the other one as output line. Each cable contains both power supply and the bus lines.

To ensure the correct wiring, the input socket on the encoder has pins (male) whereas

the output socket has holes (female). The address of the encoder is derived from its

physical position in the network. The encoder is designed for a remote bus with up to 32

bits of I/O data. In the master (controller) the actual process values occupy one or two

word addresses for profile K1 or K2 and K3, respectively.

Web :

www.beisensors.com

Male

(IB-In)

Signal

Female

(IB-Out)

1 DO 1

2 DO / 2

3 DI 3

4

DI / 4

5 GND 5

6 PE 6

7 + 10-30Vdc 7

8 GND (0V) 8

9 NC 9

IB-coupling Class Max. Bits Progr. No of words ID-code

Binary Hex

Remote Bus K1 16 No 1 IN 0000 0001 0011 0110 0136

Remote Bus K2 32 No 2 IN 0000 0010 0011 0110 0236

Remote Bus K3 32 yes 2 IN + 2 OUT 0000 0010 0011 0111 0237

ORDERING REFERENCE Contact the factory for special versions, ex: electronics, special flanges, connections…)

MHM5 IB A1 B 12 13 S 06 0 PRI

Absolute multi

turn encoder

Interbus Version

Code :

Binary

Number of

turns

2

12

(4 096)

Resolution

(pos./turn)

2

13

(8 192)

Servo

Flange

Shat

diameter :

6mm

Without

mechanical

option

M23

Connection

Changes possible without further notice - Version 100301