Operating instructions

Table Of Contents

- Front cover

- Table of contents

- Contents

- General

- Warranty

- Safety instructions

- Intended use

- Assembling and disassembling the plug-in connecting cable

- Installation

- Assembling the drive

- Undoing the mounting pin

- Drive adapter for obstacle detection

- Assembling the drive adapter with drive adapter safety catch

- Assembling the drive adapter with screw connection

- Securing the drive against axial displacement

- Fixing the drive adapter to the barrel dia. 45

- Mounting the drive in the tube

- Confirming the drive

- First operation

- Programming the master transmitter

- Checking that the running direction is correct

- Intelligent installation management

- Setting the limit positions

- Changing the set limit positions

- Deleting the limit positions

- Intermediate positions I + II

- Programming additional transmitters

- Deleting transmitters

- Overwriting the master

- Upper anti-freeze mechanism

- Obstacle detection

- Fly screen protection function

- Programming the run times

- Deleting the run times

- Disposal

- Maintenance

- Technical data dia. 45

- What to do if...?

- Sample wiring diagram

- Declaration of conformity

- Last page

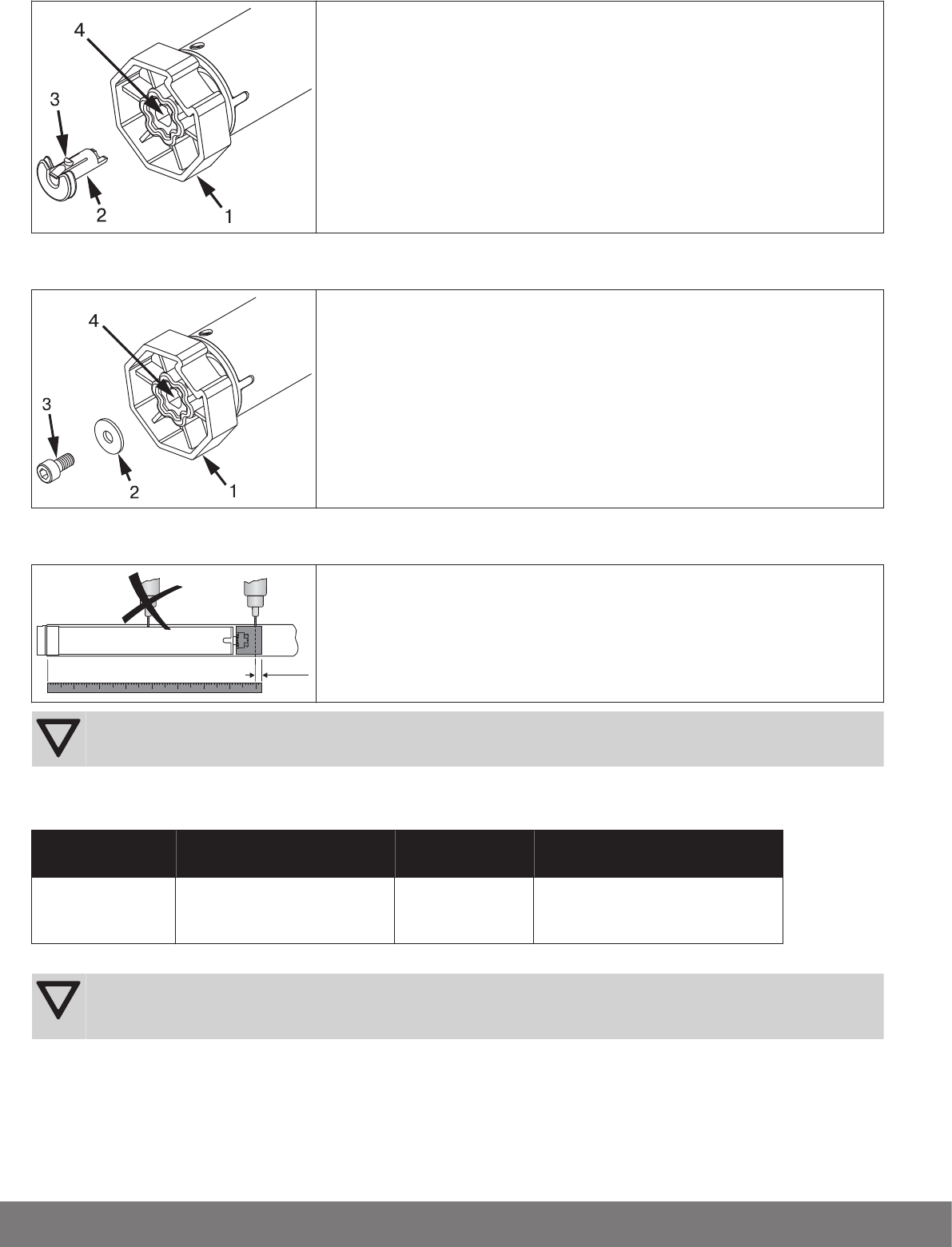

Assembling the drive adapter with drive adapter safety catch

Put the drive adapter (1) onto the drive shaft of the tubular drive. You can see which

way to insert the safety catch (2) from its shape. When inserting the drive adapter

safety catch (2) into the hole (4), make sure that the locking lug (3) engages. You will

hear a click. Check that the safety catch is securely in position by pulling on the drive

adapter (1).

Assembling the drive adapter with screw connection

Put the drive adapter (1) onto the drive shaft of the tubular drive. For the assembly,

use an M6 x 12 screw (3) with appropriate washer (2) and suitable screw retainer.

Threaded hole (4)

Securing the drive against axial displacement

-10 mm

In order to secure the drive against axial displacement, we recommend screwing the

drive adapter to the tube.

Attention

When drilling into the barrel, never drill near the tubular drive!

Fixing the drive adapter to the barrel dia. 45

Size of drive

[mm]

Diameter of barrel

[mm]

Torque

max. [Nm]

Fastening screws

for drive adapter (4 pc.)

dia. 45 60 - 70 mm

plastic or

diecast drive adapter

40 Self-tapping screw

dia. 4.8 x 9.5 mm

We also recommend screwing the opposite end bracket to the barrel.

Attention

Do not hammer or drop the tubular drive into the barrel! The curtain can only be secured using springs or anti-

lifting devices.

10