Product Manual

Page 19 of 23

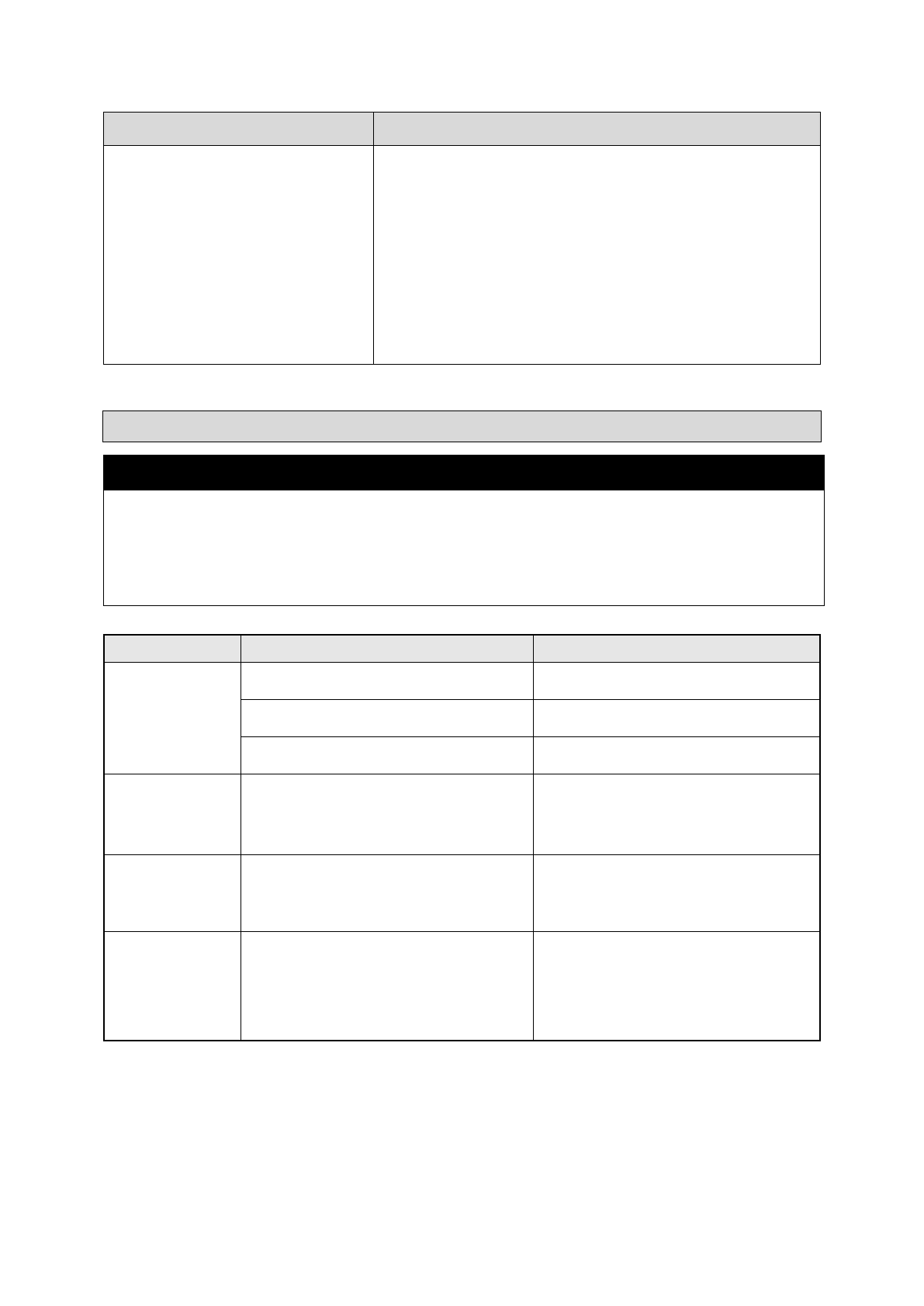

Maintenance Interval

Maintenance Point

Yearly maintenance

1. Follow all monthly maintenance procedures.

2. Check for deformed, cracked, or corroded parts, replace

them as needed.

3. Make sure all the parts as bolts,nuts,pins, or rivets are fixed

well.

4. Check for other worn, cracked, or distorted parts such as

pins, bearings, wheels, shafts, gears, rollers, locking and

clamping devices, bumpers, and stops.

Troubleshooting

⚠WARNING

TO PREVENT SERIOUS INJURY FROM CRANE FAILURE:Do not use damaged equipment.If

any defect or damage is noted,have the problem corrected before further use.

Repair or replacement of crane components must be performed only by a qualified technician

using only identical replacement parts with the same rating.

Failure

Possible Cause

Corrective Action

Cannot adjust the

I-beam height

Remove R-pins from height pins

Remove R-pins from height pins

The cable outside of pulley

Place the cable inside pulley

The gear wheel stuck in winch box

Replace the winch box

Post insert can’t

decline to the

lowest hole

height

The lifting tube’s end of post insert

cannot insert completely to the base’s

sleeve

Put the liftingtube into the base’s

sleeve

Crane won’t

move flexibly

The caster broke or is stuck

Loosen the brake or replace the caster

Post sides-are

not level

Two sides cable wind in the same

diameter

Attach one side’s R-pin, loosen the rod,

and then adjust another side’s height

by changing the cable tightness, to

keep the rod in the same level, and

then insert R-pin.