User Manual

The connection of the safety outputs must be in such a

manner that the stop command issued by the AT-

xM-11KM can not be overridden by a device or circuit

that is not at the same level of safety integrity. This

means that the safety outputs are interfaced on the

output of the machine logic (e.g., PLC or PC). Then,

normally, a feedback signal identifies to the machine

logic the status of the safety module and, if possible,

the status of the MPCEs. If interposing relays are

used, they must be of mechanically linked (forced-gui-

ded) design and monitored by the MPCE Monitoring

Circuit (Y1/Y2).

As a summary, Control Reliability (OSHA

29CFR1910.217, ANSI B11, and ANSI/RIA R15.06)

and Category 3 and 4 (ISO13849-1) requirements de-

mand that a single failure does not lead to the loss of

the safety function, or does not prevent a normal or im-

mediate stop from occurring. The failure or the fault

must be detected at or before the next demand of

safety (e.g., at the beginning or end of a cycle, or when

a safeguard is actuated). The safety-related function of

the machine control then must issue an immediate

stop command or prevent the next machine cycle or

hazardous situation until the failure or fault is correc-

ted. The user must refer to the relevant standard(s)

for complete information.

X2

MPCE1 MPCE2

A2

Y1

(1)

Y2

+24V dc

+0V dc

24V dc

Connections to

actuation devices

Z1

A1

Z2

S12

S11

S13

S22

K1 K2

13

23

S21

S23

AT-GM-11KM

AT-HM-11KM

11 5V ac

230V ac

14

24

31 32

Y30

Y31

Y32

Y33

B2 0V dc for AC hookup

B1

*

*

MPCE

1

MPCE

2

Ma chi ne

Control

Circuit

(1) See warni ng at ri ght regardi ng

in termed iate swit ching devices

(Depending on mo del )

SSI1

SSI2

(2)

(2)

M1

M2

(2) Jumper SSI input s if not used

M1 1

M1 2

M2 1

M2 2

X3

X4

X5

X6

Feedback

(op tiona l)

Z3

Z4

X1

ML

Mu te

Lamp

ME

Mu te

Enabl e

+

NOTE:

See Figures for

alternate M1/M2

hookups

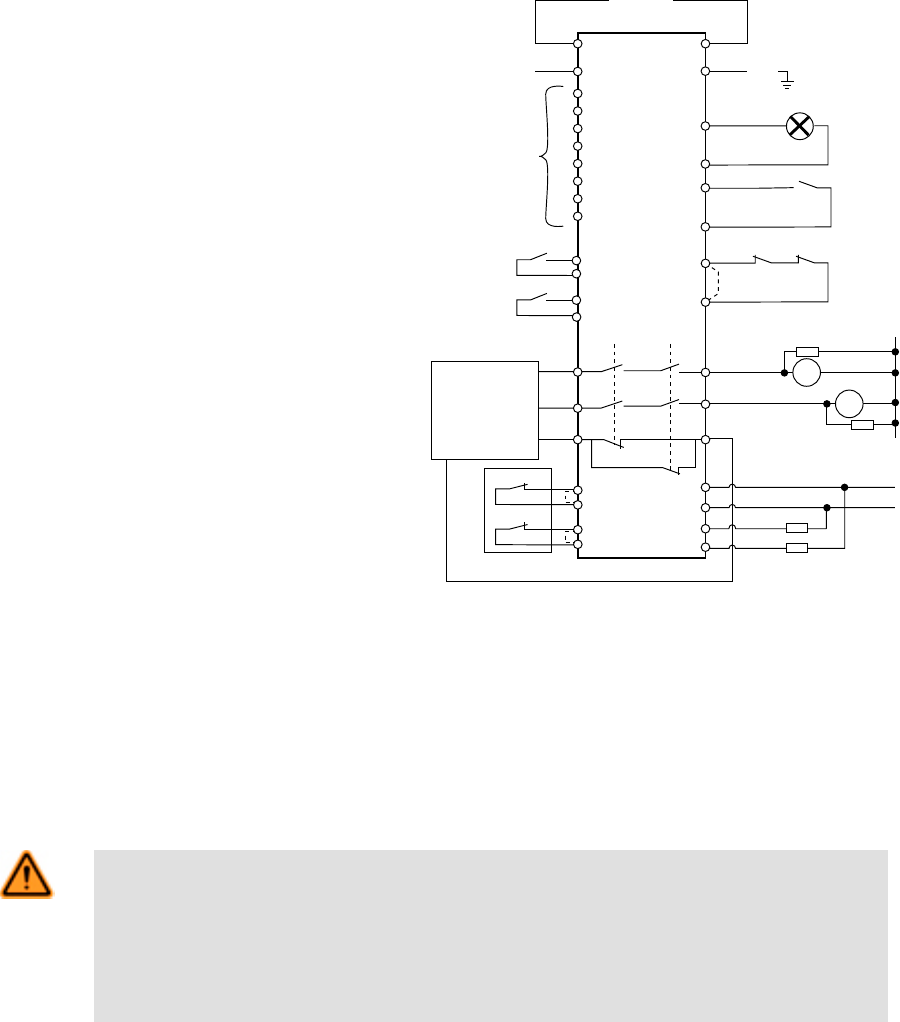

Figure 11. Machine control circuit connections

As shown in Figure 11, a normally-closed, mechanically linked monitor contact from each of the two MPCEs must be connected in series

across terminals Y1 and Y2. This allows the Safety Module to monitor the state of the MPCEs, and to prevent a successive machine

cycle, if an MPCE fault is detected. Monitoring MPCE contacts is one method of maintaining control reliability. When MPCE monitor

contacts are not available, a jumper wire must be installed across terminals Y1 and Y2.

When a jumper wire is used (dotted line between Y1 and Y2 in Figure 11), it is the user’s responsibility to provide an appropriate level of

safety for the means of machine interfacing to ensure that any single MPCE component failure will not result in the loss of safety.

WARNING: Use of Arc Suppressors

If arc suppressors are used, they MUST be installed as shown across the coils of the Machine Primary

Control Elements (MPCEs). NEVER install suppressors directly across the output contacts of the

Safety Module. It is possible for suppressors to fail as a short circuit. If installed directly across the

output contacts of the Safety Module, a short-circuited suppressor will create an unsafe condition

which could result in serious injury or death.

When switching inductive ac loads, it is good practice to protect the Safety Module outputs by installing appropriately-sized arc suppres-

sors. However, if arc suppressors are used, they must be installed across the load being switched (e. g., across the coils of external

safety relays), and never across the Safety Module’s output contacts.

DUO-TOUCH® SG Two-Hand Control Modules

12 www.bannerengineering.com - tel: 763-544-3164 P/N 109782 Rev.B