User manual

207

can contain different concentrations of agonist + antagonist. This increases the required number of

solutions and valves substantially.

However, for Dual-Line Stepper Perfusion, WinLTP can easily control 16 valves and solutions by Slow0

and Slow1 each, so WinLTP can easily control 16 concentrations.of antagonist ( Slow1) and 16

concentrations of agonist + antagonist (Slow0). The problem is more cost of the valve contollers and the

amount of solution preparation required rather than problems with WinLTP per se.

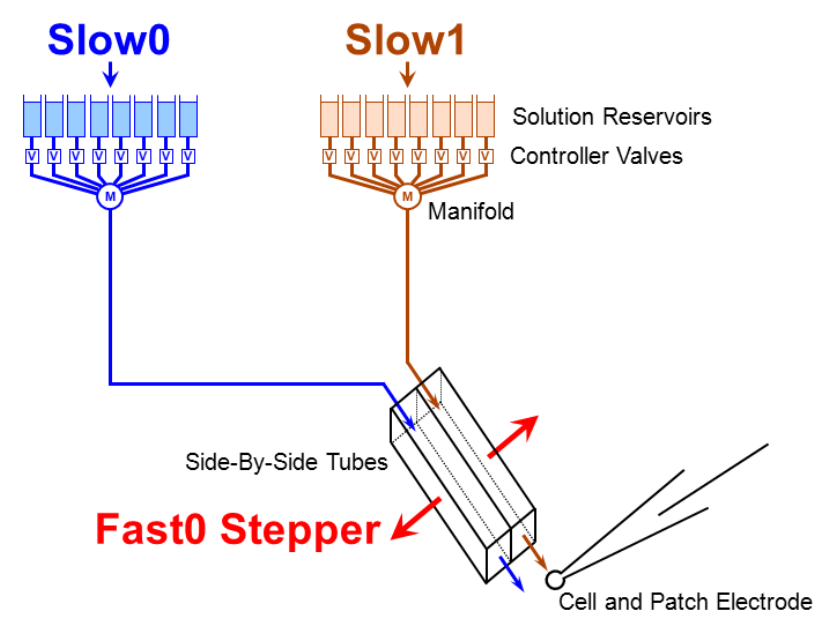

Fig. 10.4.1.1. WinLTP control of Dual-Line perfusion and a Stepper. Slow0 and Slow1 Perfusion can

control two valve controllers, and the Fast0 Perfusion controls the Stepper which controls whether

solution from Tube 0 (blue) or Tube 1 (brown) is applied to the cell. The Fast0 Stepper therefore controls

whether antagonist (Slow1) or agonist (Slow0) is applied.

Figs. 10.4.1.2, 10.4.1.3 and 10.4.1.4 show a simplified experiment involving only two tubes (Tube 0

controlled by Slow0 perfusion, and Tube 1 controlled by Slow1 perfusion), and a Fast0 controlled stepper

to switch between Tube 1 and Tube 0.

Fig. 10.4.2.2 shows how the Resources Used tabsheet is typically used for Dual-Line/Stepper perfusion.

First, in the ‘Use AD1 For’ radiobutton group, AO1 is usually used for Fast0 or Fast1 perfusion.

Then for the Automated Perfusion checkboxes, Slow0, Slow1 and Fast0 checkboxes are checked. In this

example 8-channel standard (ie 1 valve/line) digital output from Port 1 controls the Slow0 controller.

Similarly, 8-channel standard (ie 1 valve/line) digital output from Port 2 controls the Slow1 controller. By

using ‘linear’ digital output (ie one bit controlling 1 valve) rather than binary control (3 bit s controlling 8

valves or 4 bits controlling 16 valves), a single physicial controller can, in essence, be two logical