Specifications

1-15

1.10.3 Replacing the ATO board or Transformer

Disconnect the fryer from the electrical power

supply. Locate the ATO box (see Figure 1 on

page 12), behind the JIB (Jug In Box). Remove

the cover to expose the transformer and ATO

board (see Figure 2). Mark and unplug any

wires or harnesses. Replace the defective

component and reattach all wires or harnesses.

Replace the cover. Once replaced, reconnect the

power. Remove and restore power to ALL

computers after power has been restored to the

ATO board.

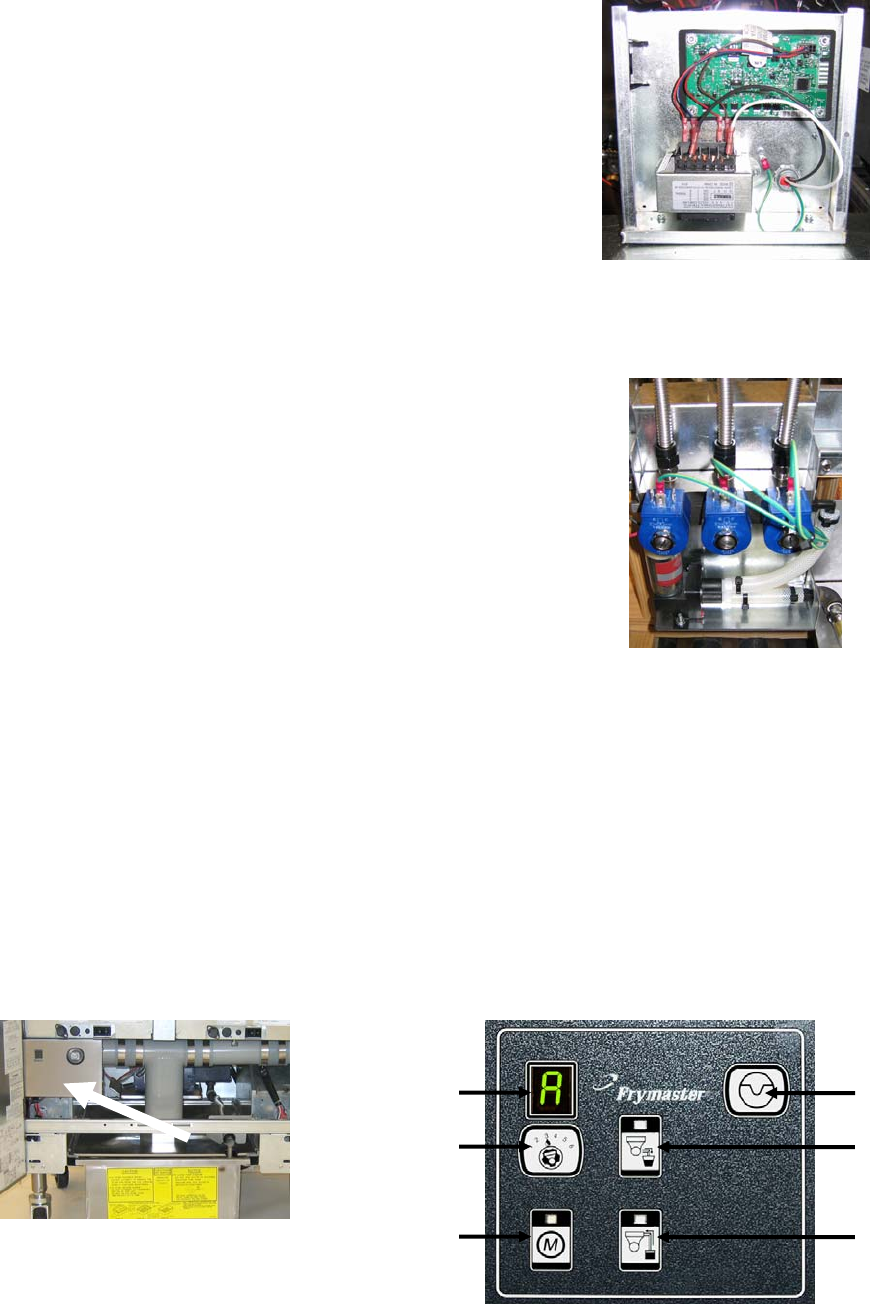

Figure 2

1.10.4 Replacing the ATO Pump or Solenoid

Disconnect the fryer from the electrical power

supply. Locate the ATO pump and solenoid tree

(see Figure 3), behind the ATO box. Mark and

unplug any wires or harnesses. Replace the

defective component and reattach all wires or

harnesses. Once replaced, reconnect the power.

Figure 3

1.11 MIB (Manual Interface Board) Service Procedures

The MIB (Manual Interface Board) oversees and controls filtration. It receives and sends data over the

CAN (Controller Area Network) to and from various sensors and computers. It activates the filtration

cycle, controlling when actuators should open and close.

The MIB controller is located inside the left cabinet (see Figure 4). In normal operation a cover hides

the MIB controls and the LED display is visible. The cover is held in place with three torx screws. In

normal operation, an “A” is displayed for automatic mode. The MIB control board is useful for

diagnostic purposes. It allows manual operation of both the actuators and filter pump without using

the M2007 computer.

Figure 4: MIB controller cover.

Figure 5

Reset Switch

Drain Switch

Return Switch

Mode Display

Vat Selector

Switch

Manual /Auto

Switch