Specifications

1-5

12. Secure any loose wires with wire ties, making sure there is no interference with the movement of

the springs. Rotate the elements up and down, making sure that movement is not restricted and

that the wires are not pinched.

13. Reinstall the tilt housing, back panels and contactor plug guards. Reposition the fryer under the

exhaust hood and reconnect it to the electrical power supply to return the fryer to service.

1.6 Replacing a Heating Element

1. Perform steps 1-5 of section 1.5, Replacing a Temperature Probe.

2. Disconnect the wire harness containing the probe wiring, where the temperature probe is attached

to the element being replaced. Using a pin pusher, disconnect the probe wires from the 12-pin

connector.

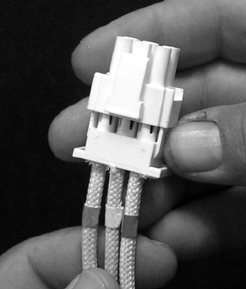

3. In the rear of the fryer disconnect the 6-pin connector for the left element (as viewed from the front

of the fryer) or the 9-pin connector for the right element from the contactor box. Press in on the

tabs on each side of the connector while pulling outward on the free end to extend the connector

and release the element leads (see photo below). Pull the leads out of the connector and out of the

wire sleeving.

4. Raise the element to the full up position and support the elements.

5. Remove the hex head screws and nuts that secure the element to the tube assembly and pull the

element out of the frypot. NOTE: Full-vat elements consist of two dual-vat elements clamped

together. For full-vat units, remove the element clamps before removing the nuts and screws that

secure the element to the tube assembly.

6. If applicable, recover the probe bracket and probe from the element being replaced and install

them on the replacement element. Install the replacement element in the frypot, securing it with the

nuts and screws removed in Step 5 to the tube assembly. Ensure the gasket is between the tube and

element assembly.

7. Route the element leads through the element tube assembly and into the wire sleeving to prevent

chafing. Ensure that the wire sleeving is routed back through the Heyco bushing, keeping it clear

from the lift springs. Also ensure that the wire sleeving extends into the tube assembly to protect

the edge of the tube assembly from chafing the wires. Press the pins into the connector in

accordance with the diagram on the following page, and then close the connector to lock the leads

in place. NOTE: It is critical that the wires be routed through the sleeving to prevent chafing.