Users Manual

9.4 Additional maintenance operations in environments with corrosive

agents

If the Radio Remote Control is used in environments where corrosive agents are present

(bywayofexample:seawater,saltfog,salt...),applygreasetotheelectricalconnections

to protect them.

Only use electrically non-conductive, polyalphaolen and silicate-based

grease for electrical contacts.

Do not use polyether-, polyoilester- and polyphenyl ether-based grease.

Macon Research's Electric Grease CN 4070 can be used.

Checkandreplacegreaseasfrequentlyasshowninthefollowingtable:

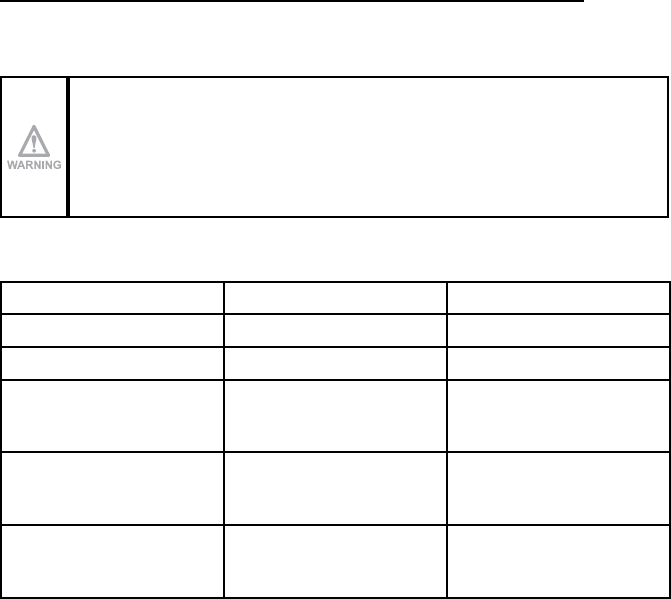

Type of connection Grease check frequency Re-greasing frequency

BNC connector for antenna every 4-6 months If dirt and impurities are found

Receiving Unit's plug every 4-6 months If dirt and impurities are found

Connectors for Transmitting

Unit's and Receiving Unit's

cable control

e

1 month

If dirt and impurities are found,

and once a year anyway

Contacts of Transmitting Unit,

Battery Charger and battery

weekly

If dirt and impurities are found,

and once every three months

anyway

Key ID 0-1 weekly

If dirt and impurities are found,

and once every three months

anyway

e. It is recommended to disconnect the cable control cable and to store it in a protected place when

it is not in use.

Whencarryingoutthiskindofmaintenanceoperations,followtheserecommendations:

- make sure that the surface of electrical connections is covered with a layer of grease

and add it if necessary,

- contactthesupportserviceoftheMachine'sManufacturerifevidentoxidationisdetected.

AUTEC - AIR SERIES

Maintenance 47

LIUAIR003_eng-01