Specifications

34

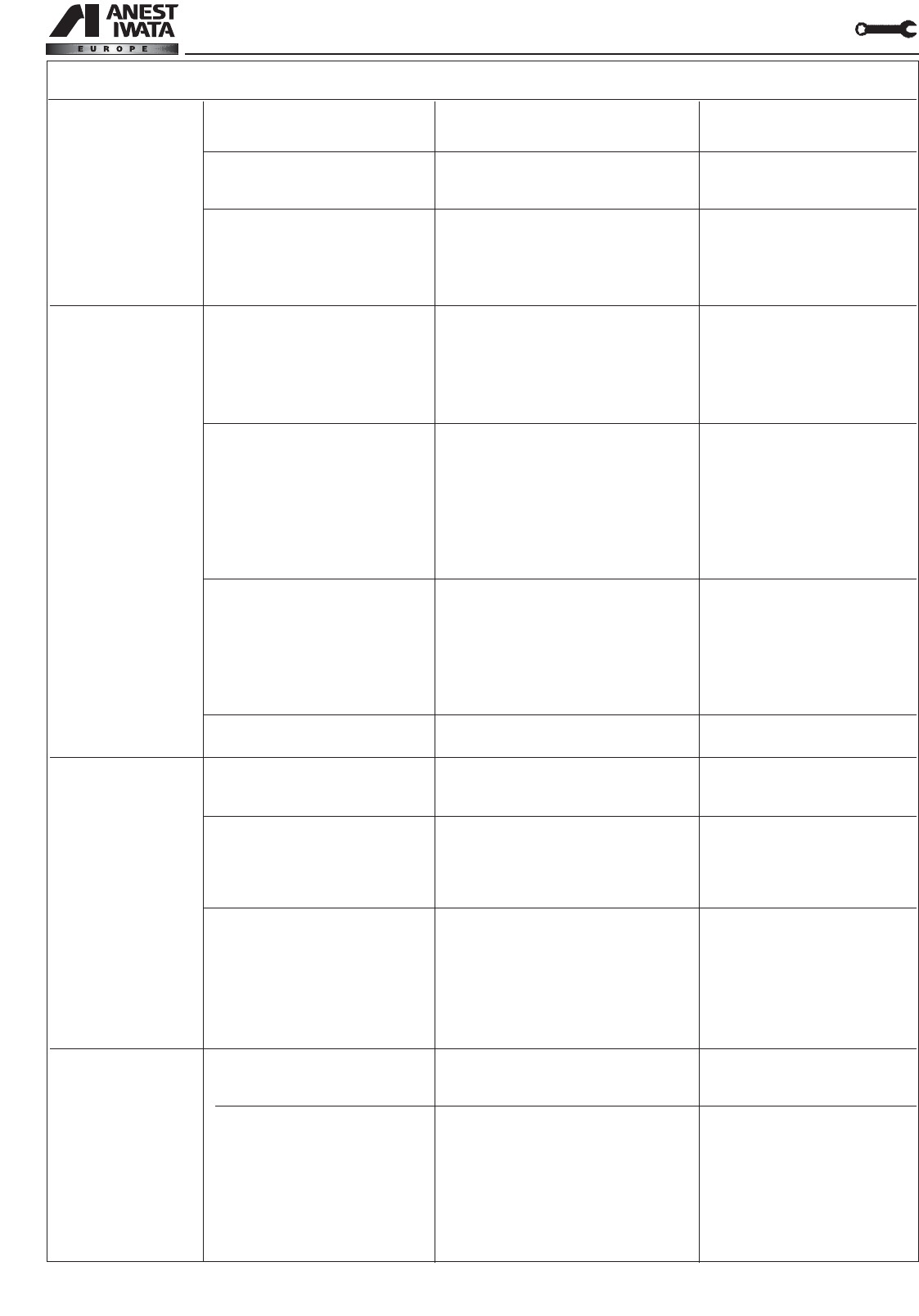

7. TROUBLE SHOOTING

Problem Cause Check Solution

1. The air pressure a) The ball valve is not in the a) Make sure the ball valve is in the a) Adjust the ball valve in

does not increase. correct position. proper position the proper position

b) The air regulator is not open. b) Check the proper operation of the b) If it is closed, open it.

regulator If it is damaged, replace it.

c) Insufficient air pressure. c) Check that the indicator of the c) If the compressor does not

pressure gauge works correctly supply enough air pressure,

replace it with one of greater

capacity

2. The paint does not a) Clogged paint filter or paint a) By opening the recirculation valve the a) The paint circuit is obstructed

flow out of the gun circuit paint does not flow out from the pump inlet to the fluid

pipe fitting. Check the paint

circuit and remove the material

obstructing the passage.

b) By opening the recirculation valve the b) The paint course, from the gun

paint flows out regularly, but not when nozzle to the fluid pipe fitting,

pulling the gun trigger. is blocked. Check for the

obstructed point and remove

the clogging; this problem is

usually caused by the obstruc-

tion of the gun filter.

c) Clogged nozzle c) Remove the nozzle and pull the trigger c) If the paint flows out it means

of the gun that the nozzle is clogged. Free

the nozzle with a steel pin and

clean it with a non-metallic

brush soaked in the suitable

solvent.

d) Safety stop jammed d) Unlock the safety valve

3. The pump does not a) The air does not supply the a) Check the air supply pipe a) Replace it if damaged or clog-

work pneumatic motor ged

b) The equipment has a technical b) Separate the pneumatic motor from the b) If the motor is running properly

problem pumping group and test it by using a follow the instructions provided

different pipe in the solution column point

2 (a-b)

c) If the motor is not running pro-

perly, disassemble the cylinder

and inspect it. In case of parti-

cular anomalies, send it to our

Customer Care Technical

Service.

4. The pump does a) Some air got inside the a) Make sure the suction hose is a)Tighten the suction hose fitting

not stop paint ducts properly connected

b) Some air remains inside b) Make sure the paint is in good b) If the paint is in standard

the paint ducts condition and that the dip tube condition increase its level

suction filter set is fully dipped at least until it fully covers the

in the product to be pumped. dip tube filter set.Then, carry

out the start-up operations

relative to the release of

air from the paint ducts.