Specifications

V

Before use, be sure to read through the Instruction Manual to insure proper use of the inverter.

V

Note that the inverter requires electrical wiring; a specialist should carry out the wiring.

V

The inverter in this catalog is designed for general industrial applications. For special applications in fields such as aircraft, outer space, nuclear

power, electrical power, transport vehicles, clinics, and submarine relay equipment, please consult with us in advance.

V

For application in a facility where human life is involved or serious losses may occur, make sure to provide safety devices to avoid a serious

accident.

V

The inverter is intended for use with a three-phase AC motor. For use with a load other than this, please consult with us.

Installation of an

AC reactor on the

input side

Using a private power

generator

Wiring connections

Installing a circuit breaker

Wiring distance

Earth leakage relay

Phase advance capacitor

Wiring

between

inverter and

motor

Electro-

magnetic contactor

Thermal relay

Notes on Peripheral Equipment Selection

An inverter run by a private power generator may overheat the generator or suffer from a deformed output voltage

waveform of the generator. Generally, the generator capacity should be five times that of the inverter (kVA) in a

PWM control system, or six times greater in a PAM control system.

(1) Be sure to connect main power wires with R, S, and T (input) terminals and motor wires to U, V, and W terminals

(output). (Incorrect connection will cause a breakdown.)

(2) Be sure to provide a grounding connection with the ground terminal ( ).

When an electromagnetic contactor is installed between the inverter and the motor, do not perform on-off switching

during running operation.

When used with standard applicable output motors (Hitachi standard three-phase squirrel-cage four-pole motors), the

SJ100 Series do not need a thermal relay for motor protection due to the internal electronic protective circuit. A

thermal relay, however, should be used:

●

during continuous running at a range beyond 30 to 60 Hz.

●

for motors exceeding the range of electronic thermal adjustment (rated current).

●

when several motors are driven by the same inverter; install a thermal relay for each motor.

●

The RC value of the thermal relay should be more than 1.1 times the rated current of the motor. Where the wiring

length is 10 m or more, the thermal relay tends to turn off readily. In this case, provide an AC reactor on the output

side or use a current sensor. See the item for the thermal relay malfunction preventive AC reactor on page 16.

Install a circuit breaker on the main power input side to protect inverter wiring and ensure personal safety. Choose an

inverter-compatible circuit breaker. The conventional type may malfunction due to harmonics from the inverter. For

more information, consult the circuit breaker manufacturer.

The wiring distance between the inverter and the remote operator panel should be 20 meters or less. When this

distance is exceeded, use CVD-E (current-voltage converter) or RCD-E (remote control device). Shielded cable

should be used on the wiring. Beware of voltage drops on main circuit wires. (A large voltage drop reduces torque.)

If the earth leakage relay (or earth leakage breaker) is used, it should have a sensitivity level of 15 mA or more (per

inverter). The leakage current differs depending on the cable length; see page xx.

Do not use a capacitor for power factor improvement between the inverter and the motor because the high-frequency

components of the inverter output may overheat or damage the capacitor

(1) High-frequency components are included in the input/output of the inverter main circuit, and they may cause interference in a transmitter, radio,

or sensor if used near the inverter. The interference can be minimized by attaching noise filters (option) in the inverter circuitry.

(2) The switching action of an inverter causes an increase in leakage current. Be sure to ground the inverter and the motor.

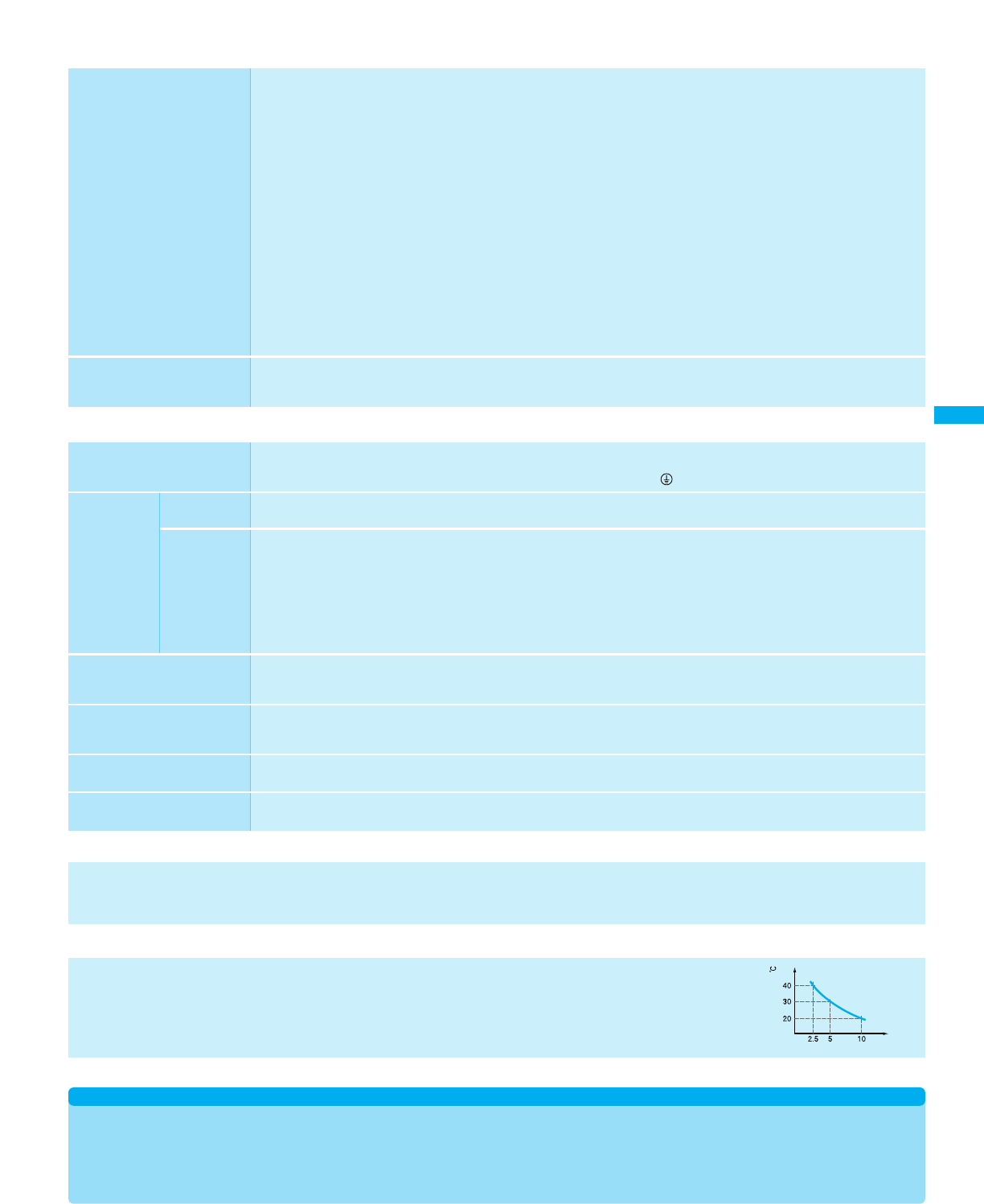

Because a smoothing capacitor deteriorates as it undergoes internal chemical reaction, it should normally be

replaced every five years. Be aware, however, that its life expectancy is considerably shorter when the inverter is

subjected to such adverse factors as high temperatures or heavy loads exceeding the rated current of the inverter.

The approximate lifetime of the capacitor is as shown in the figure at the right when it is used 12 hours daily

(according to the

‘‘Instructions for Periodic Inspection of General-Purpose Inverter’’ (JEMA).)

Also, such consumable parts as a cooling fan should be replaced. (Maintenance inspection and parts replacement

must be performed by only specified trained personnel.)

In the cases below involving a general-purpose inverter, a large peak current flows on the main power supply side,

and is able to destroy the converter module. Where such situations are foreseen or the connected equipment must

be highly reliable, install an AC reactor between the power supply and the inverter. Also, where influence of

indirect lightning strike is possible, install a lightning conductor.

(A) The unbalance factor of the power supply is 3% or higher. (Note)

(B) The power supply capacity is at least 10 times greater than the inverter capacity (the power supply capacity is

500 kVA or more).

(C) Abrupt power supply changes are expected.

Examples:

(1) Several inverters are interconnected with a short bus.

(2) A thyristor converter and an inverter are interconnected with a short bus.

(3) An installed phase advance capacitor opens and closes.

In cases (A), (B) and (C), it is recommended to install an AC reactor on the main power supply side.

Note: Example calculation with V

RS = 200V, VST = 203V, VTR = 197V

V

RS : R-S line voltage, VST : S-T line voltage, VTR : T-R line voltage

Unbalance factor of voltage =

-----------------------------------------------------------------

- T 100

=

---------------------------------

- T 100 =

---------------

- T 100 = 1.5 (%)

[Main power supply]

High-frequency Noise and Leakage Current

Lifetime of Primary Parts

Precaution for Correct Usage

Ambient temperature

)

(

Capacitor lifetime (years)

Max. line voltage (min.) - Mean line voltage

Mean line voltage

V

RS

-

(VRS + VST + VTR )/3

(V

RS + VST + VTR )/3

205 - 202

202

18

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com