User guide

Table Of Contents

- Contents

- 1.0 General information on operating instructions

- 2.0 Notes on possible dangers

- 3.0 Storage and transport

- 4.0 Description

- 5.0 Installation

- 6.0 Putting the valve into operation

- 7.0 Care and maintenance

- 8.0 Troubleshooting

- 9.0 Troubleshooting table

- 10.0 Dismantling the valve or the body

- 11.0 Warranty / Guarantee

- 12.0 EC declaration of conformity

Rev. 0040807006 1404 Page 11

Operating and installation instructions

CODI

®

S/B - Condensate collection / steam distribution

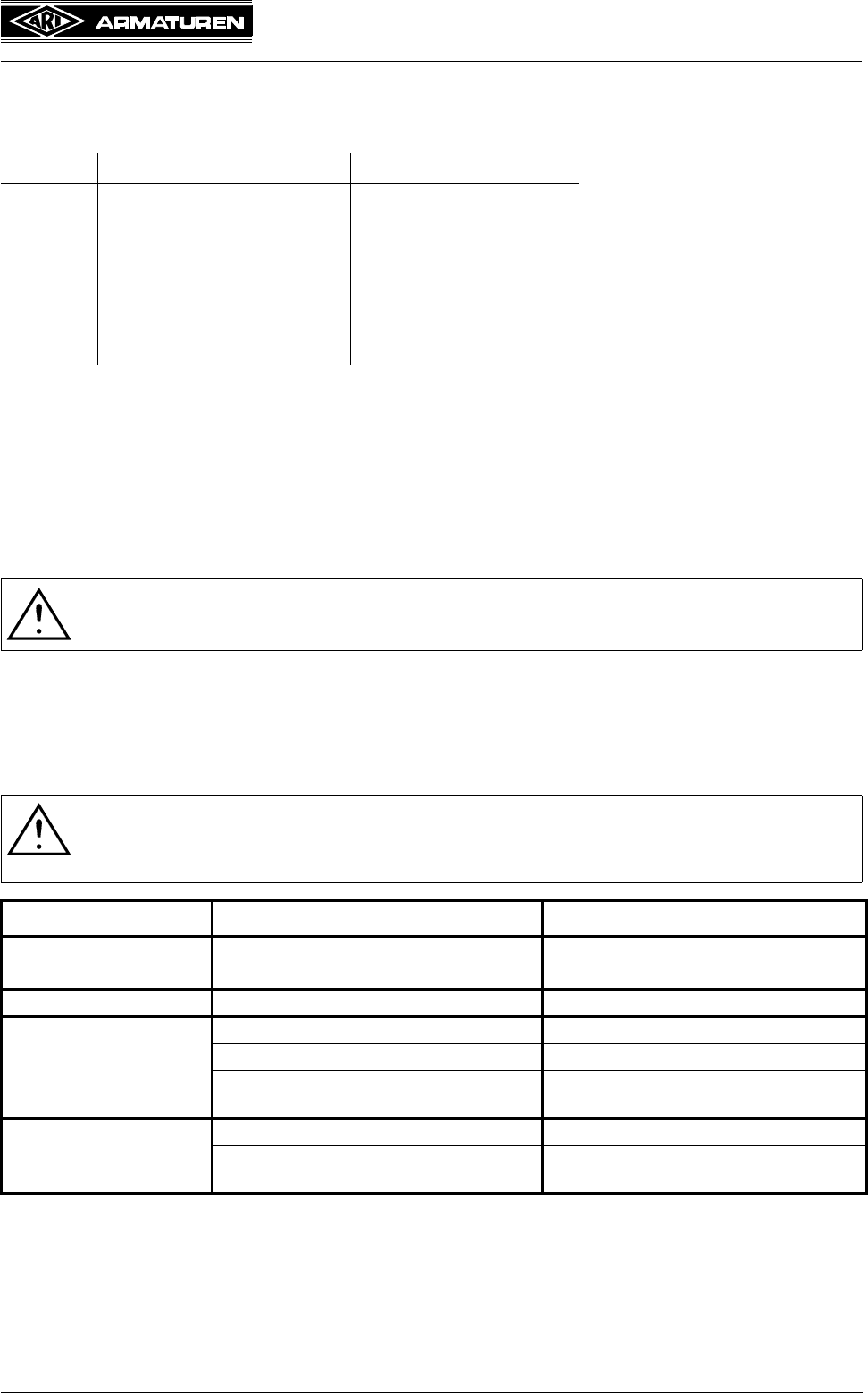

7.5 Tightening torques

(refer to Fig. 2 page 5 - Fig. 5 page 9)

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If malfunctions cannot be eliminate with the help of the following table

“9.0 troubleshooting table”, the supplier or manufacturer should be consulted.

9.0 Troubleshooting table

Pos. CODI S / B Torque (Nm)

6 Sleeve nut 10

12 Threaded bush 10

13 Safety nut 70

14 Banjo bolt 70

15 Fitting 90

16 Stem guiding 90

-

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work!

- refer to item 6.0 before restarting the plant !

Fault Possible cause Corrective measures

No flow Installed in wrong flow direction. Fit valve in direction of flow arrow

Flange covers not removed Remove flange covers

Little flow Piping system clogged Check piping system

No closure, or internal

leakage

Shut-off valve clogged Clean shut-off valve; refer to item 7.1

Shut-off valve worn Replace shut-off valve; refer to item 7.1

Shot-off valve operated above safe oper-

ating pressure

Observe operating limits as per data

sheet

External leakage Shut-off valve not properly tightened Tighten; see 7.5

Seal (Pos. 5, 10) defective Replace sealing;

refer to item 7.2 and 7.3