Operating instructions

8. Troubleshooting

8.1. Diagnosis

PROFIBUS-DP provides a flexible means of performing diagnosis of slave units, based on diagnosis

messages.

During normal cyclical data exchange, the slave can set a diagnosis bit, which requests the master

to send a diagnosis message during the next scan cycle, instead of the normal data exchange.

The slave then answers the master with a diagnosis message consisting of standard diagnosis

information, 6 bytes, and possibly extended, vendor specific, diagnosis information. The standard

diagnosis messages covers a rather limited range of general diagnosis possibilities, whereas the

extended diagnosis function offers very detailed messaging specific to the frequency converter.

The extended diagnosis messages for the frequency converter can be found in the section

Warning

word, extended status word and alarm word

.

A master or a network analysing tool will be able to translate these diagnosis words into real text

messages using the GSD-file.

NB!

DP V1 diagnosis is supported for Profibus SW version 2 and later versions. This

means that the default setting of the Profibus option is DP V1 diagnosis. If DP V0

diagnosis is required, the setting under

DP slave Properties

must be changed.

8.2. Troubleshooting

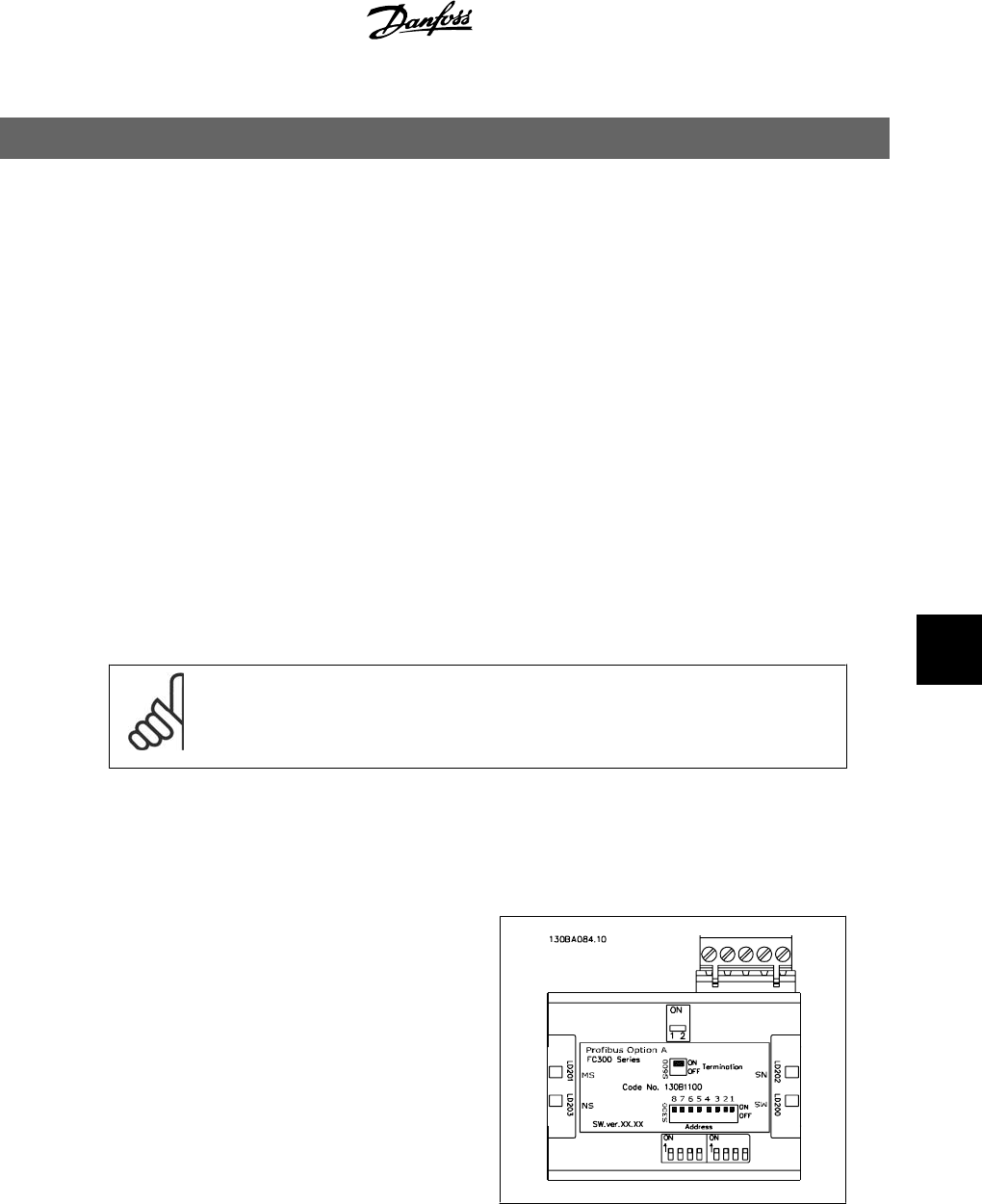

8.2.1. LED Status

First, check the LEDs. The two bi-colour LEDs

on the PROFIBUS card indicate the status of

PROFIBUS communication. The lower LED in-

dicates the Net status, i.e. the cyclical com-

munication to the PROFIBUS master. The

upper LED indicates the Module status, i.e.

acyclical DP V1 communication from either a

PROFIBUS Master Class 1 (PLC) or a Master

Class 2 (MCT10, FDT tool).

VLT

®

Profibus 8. Troubleshooting

MG.33.C4.02 - VLT

®

is a registered Danfoss trademark

89

8