Operating instructions

5.3. PCV Parameter Access

Parameter access via the PCV channel is performed by the PROFIBUS DP V0 cyclical data ex-

change, where the PCV channel is part of the PPOs described in the chapter How to Control the

Frequency Converter.

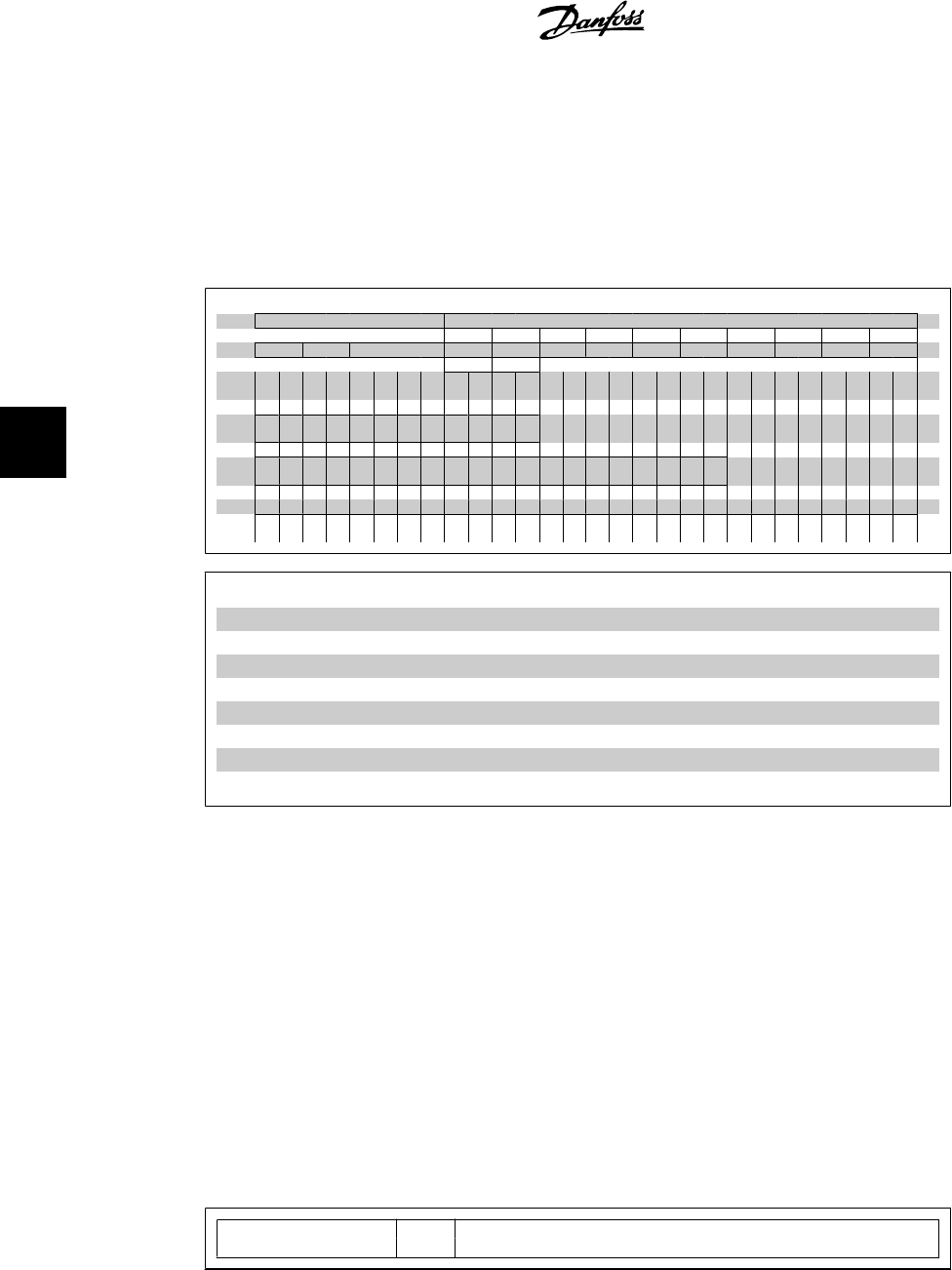

PCV PCD

1 2 3 4 5 6 7 8 9 10

PCA IND PVA CTW MRV PCD PCD PCD PCD PCD PCD PCD PCD

STW MAV

Byte

no.

1 2 3 4 5 6 7 8

9 10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Type

1:

Type

2:

Type

5:

PCV: Parameter Characteristics Value

PCD: Process Data

PCA: Parameter Characteristics (Bytes 1, 2)

IND: Sub index (Byte 3. Byte 4 is not used)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control word

STW: Status word

MRV: Main reference value

MAV: Main actual value (Actual output frequency)

Using the PCV channel it is possible to read and write parameter values, as well as readout of a

number of describing attributes of each parameter.

5.3.1. PCA Handling

The PCA part of PPO types 1, 2 and 5 can handle several tasks. The master can control and

supervise parameters and request a response from the slave, whereas the slave can respond to

a request from the master.

Requests and responses

is a handshake procedure and cannot be batched, meaning that if the

master sends out a read/write request, it has to wait for the response, before it sends a new

request. The request or response data value will be limited to maximum 4 bytes, which implies

that text strings are not transferable. For further information, please see the

Application Examples

chapter

.

5.3.2. PCA - Parameter Characteristics

15 14 13 12 11 109876543210

RC

SMP PNU

RC: Request/response characteristics (Range 0..15)

SMP: Spontaneous Messag (Not supported)

PNU : Parameter no. (Range 1..1999)

5. How to Access the Parameters VLT

®

Profibus

56

MG.33.C4.02 - VLT

®

is a registered Danfoss trademark

5