Operating instructions

Acyclical communication takes the form of a once-off data transfer event, mainly used for Read /

Write from and to parameters from process controllers, PC-based tools or monitoring SYSTEMs.

5.2.2. Features of a Master Class 1 Connection

- Cyclical data exchange (DP V0)

- Acyclical read/write from and to parameters

In general a master class 1 is used as the process controller (either PLC or PC-based), responsible

for commands, speed reference, status of the application, etc.. The master class 1 acyclical con-

nection can be used for general parameter access in the slaves. However, the acyclical connection

is fixed, and cannot be changed during operation.

5.2.3. Features of a Master Class 2 Connection

- Initiate / Abort acyclical connection

- Acyclical read/write from and to parameters

The master class 2 acyclical connection is typically used for configuration or commissioning tools

for easy access to each parameter in any slave in the SYSTEM. The acyclical connection can be

dynamically established (Initiate) or removed (Abort) even when a master class 1 is active on the

network.

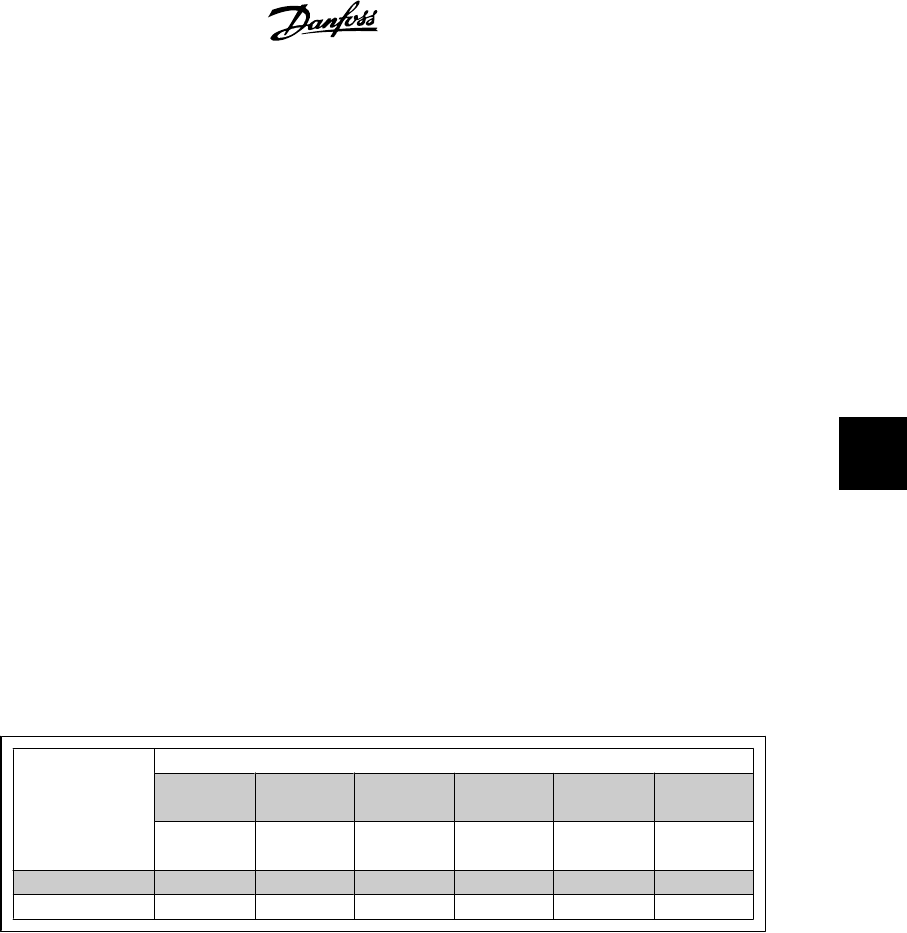

5.2.4. Services Overview for FC 100, 200 and 300

Master type Service

Read Write Data trans-

port

Initiate Abort Alarm

read data

from slave

write data

to slave

read and

write data

open a

connection

close a con-

nection

Master Class 1 yes yes yes - - -

Master Class 2 yes yes yes yes yes -

5.2.5. Principle of Data Exchange by PROFIBUS DP V1

In a DP cycle the master class 1 (MC1) will first update the cyclical process data for all slaves in

the SYSTEM. The MC1 can then send one acyclical message to one slave. If a master class 2 (MC2)

is connected, the MC1 will hand over the bus rights to MC2, which will then be permitted to send

one acyclical message to one slave. The token is then handed back to the MC1, and a new DP

cycle begins.

VLT

®

Profibus 5. How to Access the Parameters

MG.33.C4.02 - VLT

®

is a registered Danfoss trademark

45

5