Operating instructions

NB!

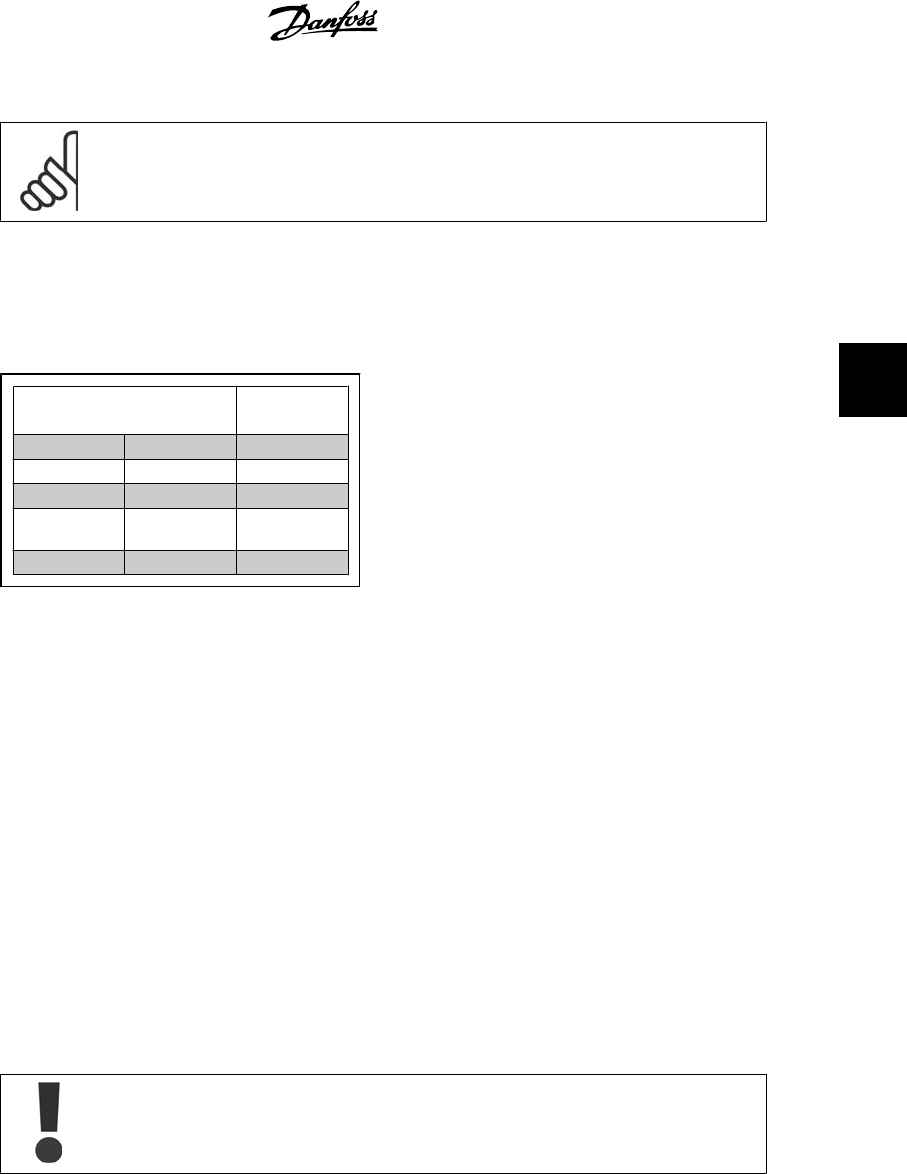

The data type for MRV and MAV is a N2 16 bit standardised value, meaning it can

express a range from -200% to +200% (8001 to 7FFF).

Par. 1-00

Configuration Mode

set to [0]

Speed open loop

.

Par. 3-00

Reference Range

set to [0]

Min - Max

.

Par. 3-02

Min Reference

set to 100 RPM.

Par. 3-03

Max Reference

set to 3000 RPM.

MRV / MAV

Actual

Speed

0% 0 hex 100 RPM

25% 1000 hex 825 RPM

50% 2000 hex 1550 RPM

75% 3000 hex 2275 RPM

100% 4000 hex 3000 RPM

4.2.4. Process Control Operation

In process control operation par. 1-00

Configuration Mode

is set to [3]

Process

.

The reference range in par. 3-00 is alway [0]

Min - Max.

- MRV represents the process setpoint.

- MAV expresses the actual process feedback (range +/1 200%).

4.2.5. Influence of the Digital Input Terminals upon FC Control Mode,

Par. 8-50 to 8-56

The influence of the digital input terminals upon control of the frequency converter can be pro-

grammed in par. 8-50 to 8-56. Please note the par. 8-01

Control Site

overrules the settings in par.

8-50 to 8-56, and Terminal 37

Coasting Stop (safe)

overrules any parameter.

Each of the digital input signals can be programmed to logic AND, logic OR, or to have no relation

to the corresponding bit in the control word. In this way a specific control command i.e. stop /

coast, can be initiated by fieldbus only, fieldbus AND Digital Input, or Ether Fieldbus OR Digital

input terminal.

In order to control the frequency converter via PROFIBUS, par. 8-50

Coasting se-

lect

must be set to either Bus [1], or to Logic AND [2], and par. 8-01

Control Site

must be set to [0] or [2].

More detailed information and examples of logical relationship options are provided in the

Trou-

bleshooting chapter

.

VLT

®

Profibus 4. How to Control the Frequency Converter

MG.33.C4.02 - VLT

®

is a registered Danfoss trademark

29

4