Specifications

OIL MATIC controller

C

ontroller

Controller (series C, CL, V and MR)

High-precision temperature control at

±0.1°C

(in stable heat-load state)

A variety of

alarm indication/output functions

A unique temperature control technology responds to a

wide range of heat load fluctuation from no load to

maximum load. Variable control of cooling capacity

allows high-precision temperature control.

The controller is provided with rich alarm

indication/output functions, including equipment

abnormality alarms (individual alarm indication and

batch output) and temperature upper/lower limit

alarm (setting, indication, and output)

Meeting various expansion needs Air filter cleaning sign

Not only simple monitoring, but also feed-forward

control that enables highly responsive temperature

control can be conducted by using a sophisticated

two-way communication function.

*The communication

method is selectable from either serial communication

(adopting RS-232C) or parallel communication (using

input/output cont

acts of PLC, etc.). Various methods of

alarm output are available.

This is a warning sign that turns on after a certain

period of operation to clean off an air filter, which is

provided to prevent an air-cooled condenser from

clogging, to prevent problems from occurring in a

refrigeration cycle.

Equipped with useful Start timer function

Auto-tuning function

OIL MATIC is equipped with the Start timer, which is

useful for starting the equipment, that allows you to set

the time at 0.1-h intervals up to a maximum of 99.9 h.

In case OIL MATIC, which is installed in an actual

machine, cannot control the temperature well, this

auto-tuning function improves the control to a good

state.

Selectable control modes

Inverter PID, gas bypass PID, ON-OFF control

Switchable between constant type (controls temperature to the preset temperature) and

reference temperature follow-up type (controls temperature following the reference

temperature)

Switchable between sending (outlet) liquid temperature control and return (inlet) liquid

temperature control

Cascade control and control at use point are possible.

* The lights are being turned on for photographic purpose only, and the lighting may be different

from the actual state.

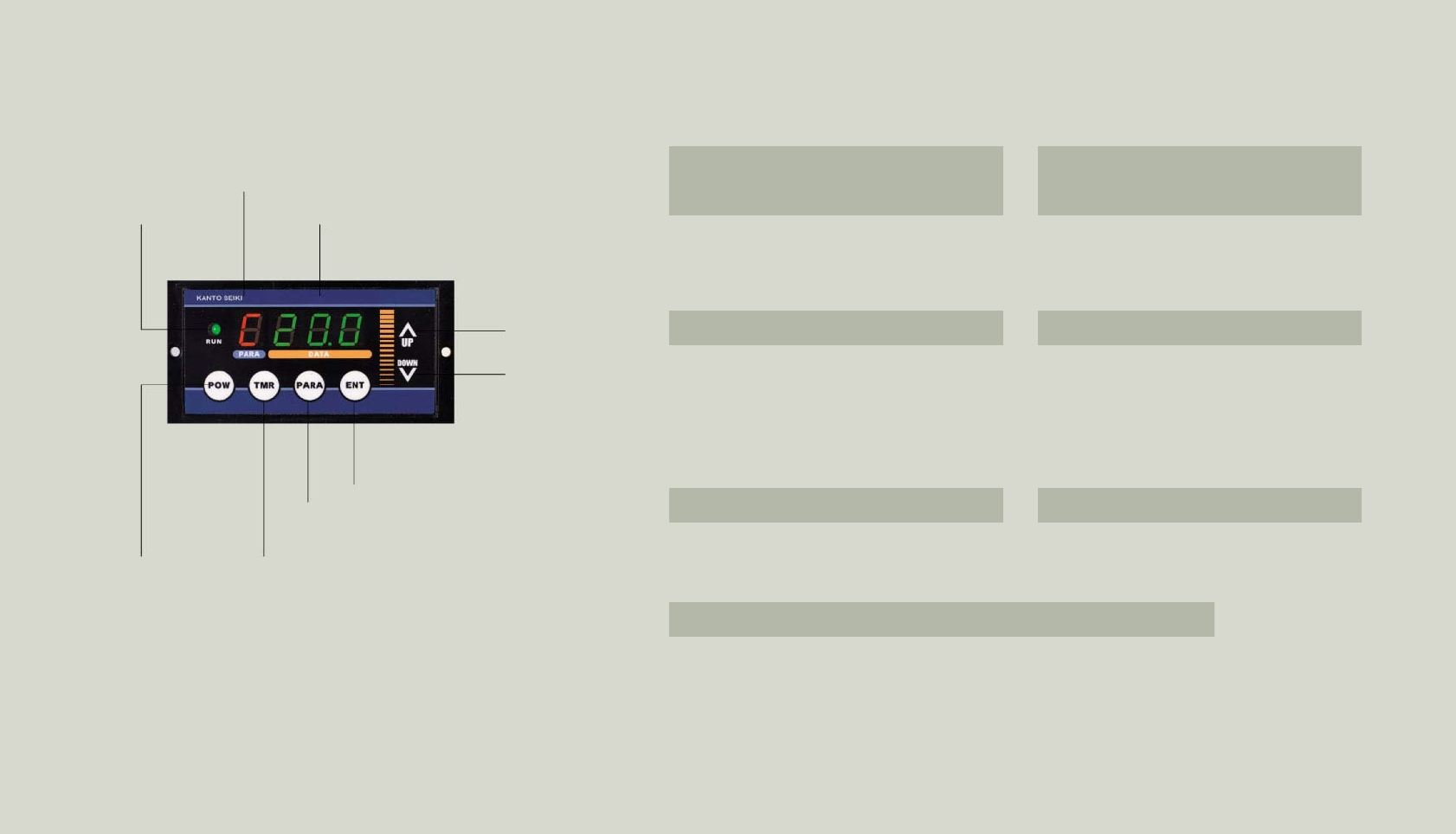

Parameter indicating LED

RUN lamp

Turns on during

operation

(Turns off at alarm)

Data indicating LED

UP key

(key for

increasing set value)

DOWN key

(key for

decreasing set value)

ENT key

Key for indicating current temperature

PARA key

Key for setting parameters

TMR key

Key for setting Start timer

(for models with timer)

POW key

Key for starting/stopping

OIL MATIC