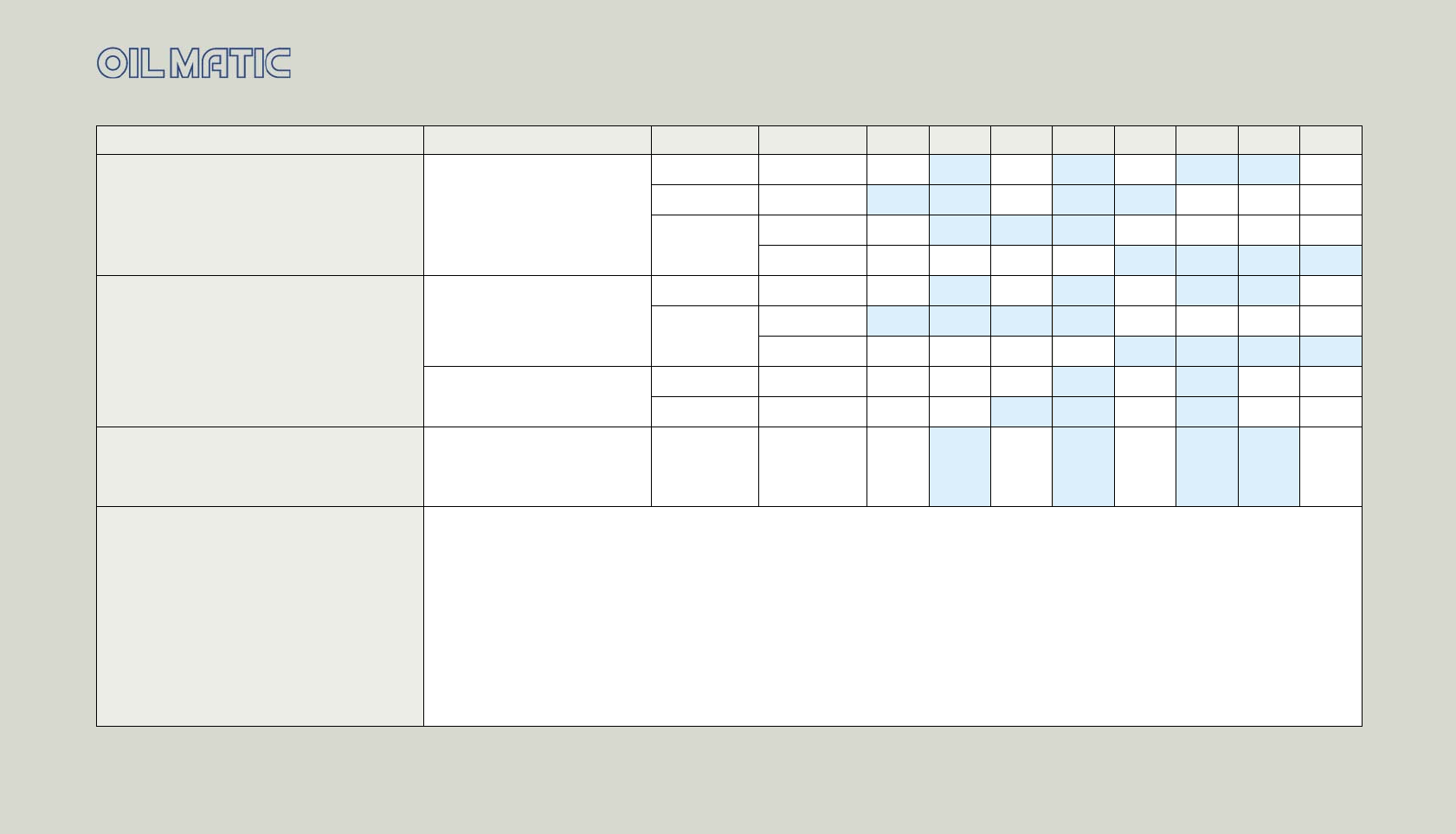

Specifications

Lineup of OIL MATIC product series

S

eries

-series products classified by application <list>

Application Liquid used* Series name Control method

Model

01

Model

03

Model

05

Model

07

Model

11

Model

15

Model

22

Model

38

For cooling main spindle

For controlling operating

oil temperature

For controlling lubricant oil

temperature

For cooling ball screws

For cooling linear motor / DD

motor

Oil

Circulation (closed) type

Series C

Inverter control

Series CL

Gas bypass

PID control

Series ML

ON-OFF control

Gas bypass

ON-OFF control

For controlling coolant

temperature

For cooling ball screws

For cooling machine body

For cooling linear motor /

DD motor

Oil

Water

Coolant

Open type

Series V

Inverter control

Series KTV

ON-OFF control

Gas bypass

ON-OFF control

Oil

Coolant

Circulation (closed) type

(Disassembled cleaning of cooler is possible)

Series MRCC

Inverter control

Series MLCC

(KTCG)

ON-OFF control

For cooling main spindle

For cooling ball screws

For cooling laser oscillator

For cooling linear motor / DD

motor for semiconductor

manufacturing equipment

For physical and chemical

equipment

Water

Circulation (closed) type

Series W

Inverter control

Various other special specifications

For controlling temperature of ultra-precision (microfabrication) machines:

Ultra-precision-class liquid temperature control: ±0.001-0.05 (°C)

· Ultra-precision temperature control of hydrostatic bearings and operating oil for guide

· Ultra-precision temperature control of spindle head

· Ultra-precision temperature control of machining fluid

For temperature control of semiconductor manufacturing equipment:

High-precision liquid temperature control within ±0.1-1.0 (°C), ultra-precision-class liquid

temperature control within ±0.001-0.05(°C), multi-system temperature control

· Cooling spindles of dicer, slicer, grinder, polishing lathe and controlling temperature of

machining fluid

· Cooling laser oscillator

· Controlling temperature of stage and drive section in exposure equipment

· Controlling plasma electrode temperature of etcher, PVD and CVD equipment

· Controlling temperature of tester/prober chuck

· Ultra-low cooling for various applications

For controlling temperature of medical,

physical and chemical equipment:

For controlling printer temperature:

For controlling temperature of washing

equipment:

For controlling temperature of molding

machines and dies:

For independent temperature control of

multi-systems:

For ultra-low cooling for various

applications:

- Cooling W-ray tube

- Controlling printer roll

temperature

- Controlling temperature of

pure water for washing, etc.

- Automatic die temperature

regulator (MOLDMATIC)

* Please consult us for designing and fabrication of various products with special specifications (such as OEM specifications, special shape specifications, water-cooled condenser specifications, different voltage specifications, tropical treatment specifications and various

safety-standard specifications) other than the above.

* There may be restrictions depending on component and viscosity of liquid to use. Please contact us for details.