User guide

Table Of Contents

- Table of Contents

- List of Figures

- List of Tables

- Foreword

- 1 Introduction

- 1.1 Model 4Q1010PS-430 Integrated Power Supply System Features

- 1.1.1 Digitally-Controlled

- 1.1.2 Superior Resolution and Stability

- 1.1.3 Intuitive Human-Interface Design

- 1.1.4 Flexibility

- 1.1.5 Standard Remote Interfaces

- 1.1.6 Programmable Safety Features

- 1.1.7 Condition-Based Magnet Auto-Rampdown

- 1.1.8 Model 4Q1010PS-430 General Description

- 1.1.9 Power Supply System Rack Front Panel Layout

- 1.2 Model 430 Front Panel Layout

- 1.3 Model 430 Rear Panel Layout

- 1.4 Power Supply Unit Front Panel Layout

- 1.5 System Specifications @ 25 C

- 1.6 Operating Characteristics

- 1.1 Model 4Q1010PS-430 Integrated Power Supply System Features

- 2 Installation

- 3 Operation

- 3.1 System Power On/Off Sequence

- 3.2 Model 430 Programmer Default Display

- 3.3 Entering Numeric Values

- 3.4 Using Fine Adjust Knob to Adjust Numeric Values

- 3.5 Entering Picklist Values

- 3.6 Single-key Commands / Menu

- 3.7 SHIFT-key Commands / Menus

- Figure 3-5. SHIFT-Key Functions

- 3.7.1 Ramp Rate SHIFT-key

- 3.7.2 Voltage Limit SHIFT-key

- 3.7.3 Reset Quench SHIFT-key

- 3.7.4 Increment Field SHIFT-key

- 3.7.5 Field <> Current SHIFT-key

- 3.7.6 Decrement Field SHIFT-key

- 3.7.7 Field Units SHIFT-key

- 3.7.8 Persistent Switch Heater Current SHIFT-key

- 3.7.9 Stability SHIFT-key

- 3.7.10 Vs <> Vm SHIFT-key

- 3.7.11 Volt Meter SHIFT-key

- 3.7.12 Fine Adjust SHIFT-key

- 3.7.13 Persist. Switch Control SHIFT-key

- 3.8 LED Indicators

- 3.9 Setup Menu

- 3.10 Setup Submenu Descriptions

- Figure 3-7. Setup Menu Structure

- 3.10.1 Supply Submenu

- 3.10.2 Load Submenu

- 3.10.2.1 Stability Setting

- 3.10.2.2 Coil Constant

- 3.10.2.3 Magnet Current Rating

- 3.10.2.4 Current Limit

- 3.10.2.5 Calculate Magnet Inductance

- 3.10.2.6 PSwitch Installed

- 3.10.2.7 PSwitch Current Detect (mA)

- 3.10.2.8 PSwitch Current

- 3.10.2.9 PSwitch Heated Time

- 3.10.2.10 PSwitch Cooled Time

- 3.10.2.11 PSwitch Power Supply Ramp Rate

- 3.10.2.12 PSwitch Cooling Gain

- 3.10.2.13 Enable Quench Detect

- 3.10.2.14 Energy Absorber Present

- 3.10.2.15 Enable External Rampdown

- 3.10.3 Misc Submenu

- 3.10.4 Net Settings Submenu

- 3.10.5 Net Setup Submenu

- 3.11 Example Setup

- 3.12 Ramping Functions

- 3.13 Persistent Switch Control

- 3.14 Ramping Functions Example

- 3.15 Quench Detection

- 3.16 External Rampdown

- 3.17 Summary of Operational Limits and Default Settings

- 4 Remote Interface Reference

- 4.1 SCPI Command Summary

- 4.2 Programming Overview

- 4.3 RS-232 Configuration

- 4.4 Ethernet Configuration

- 4.5 Command Reference

- 4.5.1 System-Related Commands

- 4.5.2 Status System Commands

- 4.5.3 SETUP Configuration Commands and Queries

- 4.5.4 Protection Commands and Queries

- 4.5.5 Ramp Configuration Commands and Queries

- 4.5.6 Ramping State Commands and Queries

- 4.5.7 Switch Heater Command and Query

- 4.5.8 Quench State Commands and Queries

- 4.5.9 Rampdown State Queries

- 4.5.10 Trigger Functions

- 4.6 Error Messages

- 5 Service

- 5.1 System Component Maintenance

- 5.2 Troubleshooting Hints

- 5.2.1 Electrostatic Discharge Precautions

- 5.2.2 The Model 430 does not appear to be energized

- 5.2.3 FAILURE TO LOAD message displayed after power-up

- 5.2.4 Power supply unstable - magnet voltage oscillates

- 5.2.5 The power supply system will not charge the magnet.

- 5.2.6 Cannot charge the magnet at the selected ramp rate.

- 5.2.7 Cannot discharge the magnet at the selected ramp rate

- 5.2.8 Cannot charge the magnet to desired field.

- 5.2.9 Current in only one direction from 4-quadrant supply

- 5.2.10 Cannot place the magnet in persistent mode.

- 5.2.11 Cannot bring the magnet out of persistent mode.

- 5.2.12 The magnet quenches for no apparent reason

- 5.2.13 Cannot lower the magnet field

- 5.2.14 There is excessive LHe boil-off during operation.

- 5.2.15 Cannot display the magnetic field strength, only current

- 5.2.16 Cannot use remote communications commands.

- 5.2.17 Magnet current drifts unacceptably while PSwitch cooling

- 5.2.18 Model 430 appears to lock up when connecting to network

- 5.3 Additional Technical Support

- 5.4 Return Authorization

- Appendix

- A.1 Magnet Station Connectors

- A.2 LHe Level / Temp Connectors

- A.3 Programmer Shunt Terminals

- A.4 Program Out Connector

- A.5 Quench I/O Connector

- A.6 Aux Inputs Connector

- A.7 Ethernet Connector

- A.8 RS-232 Connector

- A.9 Abbreviations and Acronyms used in this Manual

- A.10 Model 430 Programmer Specifications

- A.11 Power Supply Details

- A.12 Remote Computer Communication with the Model 430

- A.13 Upgrading the Model 430 Firmware via FTP

- A.14 Upgrading the Model 430 Firmware via Flash Card Reader

- A.15 Model 430 Remote Control Application

- A.16 Model 430IP Power Supply Programmer

- A.17 Persistent Switch Operation Flowchart

- Index

Rev. 5 9

Introduction

Operating Characteristics

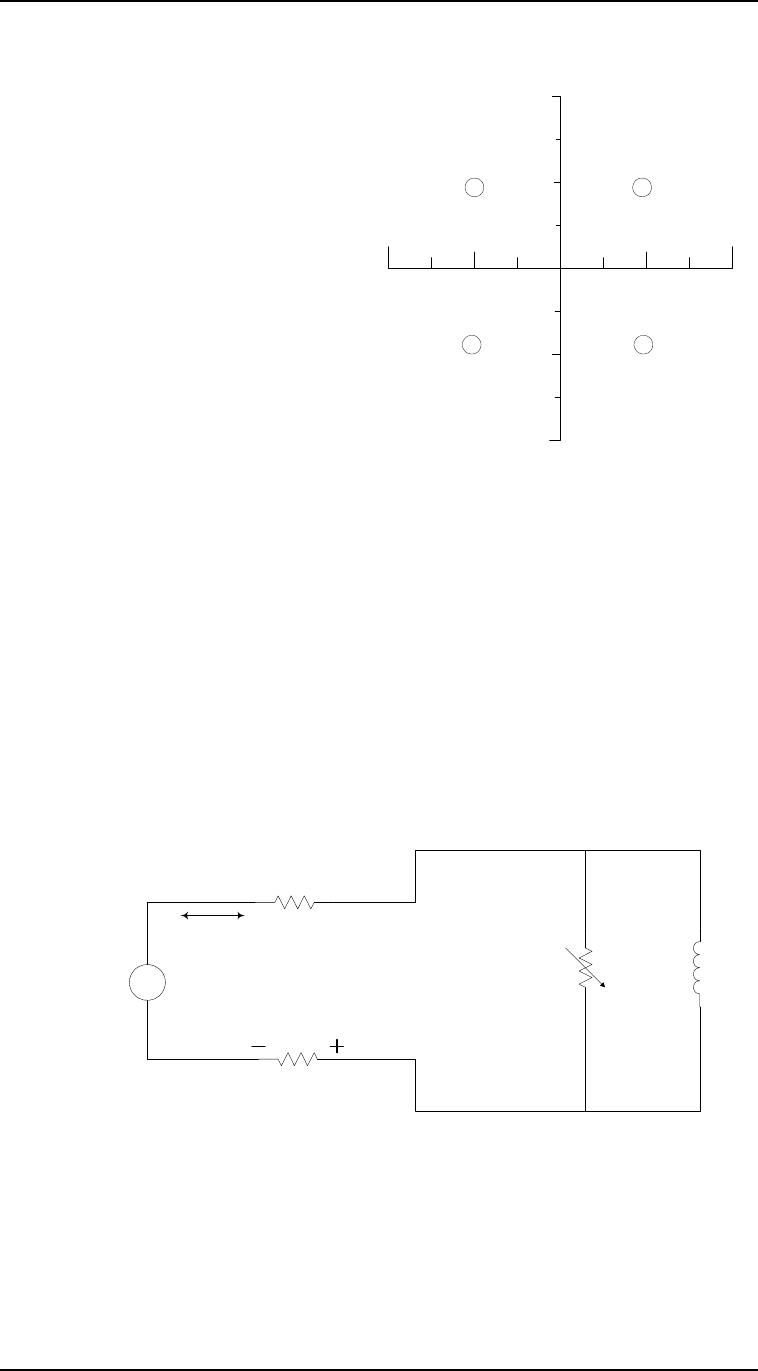

1.6 Operating Characteristics

The Model 430 Programmer has

been designed to perform with var-

ious power supplies to allow the

user the greatest degree of system

flexibility. The power supply and

Programmer combination are cate-

gorized by one of three forms: sin-

gle-quadrant, dual-quadrant, and

four-quadrant. For sake of clarity,

the term quadrant is defined as

one of four areas of a cartesian

coordinate system where the

abscissa is current and the ordi-

nate is voltage. Refer to Figure 1-3.

1.6.1 Four-Quadrant Operation

The four-quadrant magnet power supply system illustrated in Figure 1-4

offers the most control of all the modes of operation. Efficiency is increased

and reversible magnetic field profiles are attainable without

discontinuities in the current. All of the voltage and current control is

performed electronically so that system reliability is improved.

Disadvantages of the four-quadrant system include somewhat increased

cost of the power supply over single or dual-quadrant power supplies, and

added complexity in protecting the power supply in the event of AC power

loss or magnet quenching. Nonetheless, modern four-quadrant power

supplies which include integral output protection against AC power loss

and magnet quenching are available at reasonable prices.

20

-20

200-200

V

I

Positive Current

Flow Direction

Positive Voltage

Polarity

Positive Current

Flow Direction

Negative Voltage

Polarity

Negative Current

Flow Direction

Positive Voltage

Polarity

Negative Current

Flow Direction

Negative Voltage

Polarity

12

43

Figure 1-3. The Four Regions, or

Quadrants, of System Operation.

Magnet

Coil(s)

Persistent

Switch

(optional)

Misc. Line Losses

Model 420

Shunt

V

Four-Quadrant

Power Supply

Current

Figure 1-4. Four-Quadrant System with Resistive Shunt

430