MANUAL Alpha® Variable Speed Wet Polisher Instruction Manual Model No.: VSP-230 WARNING: To reduce the risk of injury, user must read and understand instruction manual! 103 Bauer Drive, Oakland, NJ 07436 • 800-648-7229 • Fax: 800-286-0114 www.alpha-tools.

TABLE OF CONTENTS VSP-230 Overview ............................................................................................ 3 Specifications ............................................................................................. 3 Accessories ................................................................................................ 4 Introduction ........................................................................................................ 5 About the Symbols .......................

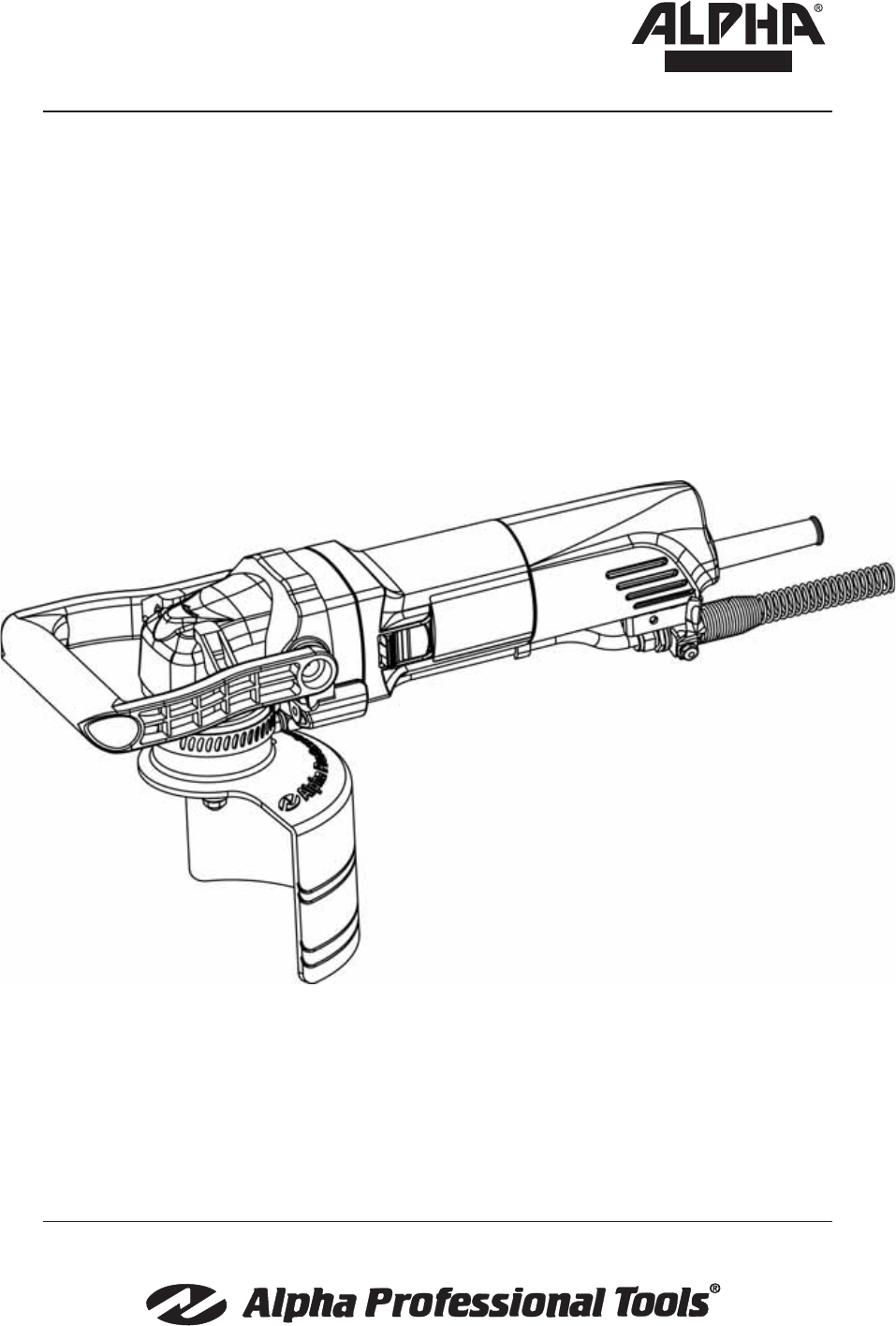

VSP-230 OVERVIEW Speed Adjuster Power Switch “C” Handle Band Clamp Water Valve In-line GFCI Center Water Feed Water Line Splash Guard Garden Hose Adapter Figure-1 SPECIFICATIONS Working Power Supply ................................................... Single-phase AC, 50/60 Hz Voltage ........................................................................... 230V Plug Type ....................................................................... C (230V) Amperage .......................................

ACCESSORIES COMPONENTS: 1. 2. 3. 4. 5. 4 Side Handle (Part No. 210074) Wrench (Part No. 210073) Band Clamp (Part No. 210088) Splash Guard (Part No. 210089) Spare Set of Carbon Brushes (Part No.

INTRODUCTION Thank you for purchasing the Alpha® Wet Polisher. Please read this instruction manual thoroughly to ensure safety and correct use of the polisher. Keep this manual in a place where operators can access it easily whenever necessary. ABOUT THE SYMBOLS According to the hazard level, all safety notes in this manual are classified into “DANGER”, “WARNING”, and “CAUTION”. DANGER! Death or serious personal injury is imminent when handling this polisher incorrectly.

CAUTION! The following are important notes for products, operation, and maintenance applicable to this polisher. GENERAL SAFETY RULES WORK AREA • • • Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents. Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools may create sparks which may ignite the dust or fumes. Keep bystanders, children, and visitors away while operating a power tool.

• • • • • • • • • • • Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations. Do not use on a ladder or unstable support. Use safety equipment. Always wear eye protection.

SPECIFIC SAFETY RULES • • • • • • • • • • • • • • • 8 Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over rated speed can fly apart and cause injury. Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator. Know your power tool.

USE PROPER EXTENSION CORDS Use only three-wire extension cords that have three-prong grounding-type plugs and three-pole receptacles that accept the tool’s plug. Make sure your extension cord is in good condition. Replace or repair damaged or worn cord immediately. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating.

ADDITIONAL PRECAUTIONS FOR USING THE VSP-230 In addition to the general safety notes described on the preceding pages, please read and observe the following precautionary notes before using the polisher. DANGER! 1. 2. 3. 4. 5. 6. 7. 8. 9. Check the working voltage. Be sure the voltage available at power outlet matches specified voltage on the nameplate. If the polisher is used with higher voltage than specified, the motor will burnout.

. Observe any suspicious abnormal noises when a polishing disc is attached for the first time and polisher is turned ON. It may cause bodily injury if the polishing disc flies off. 12. Do not touch the polishing disc while spinning. The polishing disc spins very fast and you may hurt yourself. 13. Be careful of your surroundings when working in high places. When working in high places, make sure there are no people below.

VSP-230 VARIABLE SPEED WET POLISHER OPERATION CAUTION! Always be sure that the tool is switched off and unplugged before adjusting or checking function on tool. MAIN CONNECTION Connect only to single-phase AC current supply and only to the main voltage specified on the rating plate. SWITCHING ON AND OFF CAUTION! Before plugging in the tool, always check the working voltage be sure that the voltage specified is on the name plate.

GROUND FAULT CIRCUIT INTERRUPTER (GFCI) A Ground Fault Circuit Interrupter is built in-line with the power supply cord to protect the operator from electric shock. 1. GFCI Information. – Alpha® Wet Polisher is provided with an in-line GFCI as a standard accessory for your safety, and to prevent possible electric shocks. It is strongly advised to test the GFCI on a regular basis. DANGER! Never attach a damaged extension cord to the polisher. NOTE: Use the appropriate extension cord, see table on page 9.

TESTING IN-LINE GFCI UNIT (Before Each Use Of The Polisher) 1. Connect polisher to a single phase AC power supply. 2. Verify that the indicator lens shows red (indicating output voltage). 3. Press the test button to verify that the red in the indicator lens disappears. 4. Press the reset button to verify the red indicator is visible. 5. The GFCI is now ready for use. WARNING! DO NOT USE IF ABOVE TEST FAILS! RESET BUTTON Indicator viewing lens. RED lens shows power to polisher.

SPEED POT FEEDBACK SENSOR This polisher is equipped with a Closed Loop Feedback sensor that is attached to the speed pot. When a load is applied to the tool, the sensor will re-adjust the RPM to maintain a constant speed. WATER CONTROL VALVE CAUTION! Adjust the water flow to wet the stone and remove waste, excessive spray and mist will get inside the tool and cause premature failure of the tool and/or cause the GFCI to trip. This polisher is equipped with a center water-feed system.

SIDE HANDLE INSTALLATION CAUTION! During the use of Alpha® Core Bits and Profilers, use of the center handle is recommended. The center handle will allow the operator to have better control and ease of operation during these applications. To switch from center handle to side handle, follow the steps below: Remove both side screws from center handle. Figure-12 Pull handle forward and clear of polisher.

CUSTOMIZING THE SPLASH GUARD The splash guard can be cut to different heights according to the application to be performed. Cutting: Using a pair of scissors or other cutting instrument, choose the desired height according to the application to be performed and cut along the grooved cut lines, as shown in Figure 15. Grooved Cut Lines Figure-15 RECOMMENDED HEIGHTS: Profiling: When using Alpha® Profilers the splash guard can be used at its full height.

SPLASH GUARD INSTALLATION CAUTION! The splash guard should be used to prevent the water and dust from going inside the tool. Failure to do so can shorten the life of your tool and void the limited warranty. 1. Install the rubber splash guard into the tool so that the lip on the splash guard fits into the groove on the tool and the cutout is around the water fitting. 2. Open the band clamp completely and wrap around the splash guard under the water fitting. 3. Tighten the clamp until snug.

PROFILER AND OTHER APPROVED SPINDLE ATTACHMENTS CAUTION! Do not leave threaded accessories on the spindle of the tool for extended periods of time, as this may result in making it difficult to remove these accessories. The VSP-230 polisher has a M14-2 center water-feed spindle thread. To attach a profiler wheel or other approved spindle attachments, follow the steps below: 1. Screw the attachment onto the spindle by hand. Figure-21 2. Tighten with supplied wrench.

CAUTION! Always wear safety goggles or a face shield during operation. Never switch on the tool when it is in contact with the workpiece, it may cause an injury to operator. Never run the tool without properly installed accessories. Make sure that the water valve is closed. Connect the garden hose adapter to the water source. Make sure that water comes out when the water valve is opened. Hold the tool firmly. Turn the tool on and begin your application. Apply slight pressure only.

Periodic maintenance is done to check the tool and to minimize down time. These checks are done based on hours of operation and operating conditions. Operating condition can vary depending on the work surface and job being preformed. If the tool is not used for a long period of time the carbon brushes should be checked and the commutator cleaned, before putting the tool back into operation.

REAR COVER REMOVAL 1. Gently pull water tube away from holder. Figure-24 2. Release the tube from the holder. Figure-25 3. Unwrap 3 inches of the coiled harness. Figure-26 4. Remove the 2 screws from the valve bracket.

5. Pull the valve assembly away from mount. Figure-28 6. Remove the rear case screw. Figure-29 7. Hold polisher with one hand and pull the rear case straight back with the other hand. NOTE: Do not twist case in a side to side motion when pulling back. Figure-30 8. Pull back the rear case until the carbon brush assembly is exposed. NOTE: Do not pull rear case further back from this point.

Carbon Brush Spring Carbon Brush Holder Carbon Brush Wire Figure-32 9. Lift the spring from the carbon brush and place on the side of the brush holder. Figure-33 10. Remove the carbon brush wire spade connector from the terminal post and then remove the carbon brush.

11. You can also remove the carbon brush by removing the screw and pulling the holder out with a pair of needle nose pliers. 12. With the carbon brush holder removed, you can check and clean the armature commutator. The commutator is the contact points that the carbon brushes ride on when the motor is running. Figure-36 NOTE: Each polisher has 2 carbon brushes located on opposite sides of each other. After the replacement of the two brushes, assemble the polisher by reversing disassembly procedure. 13.

16. The commutator should be clean and shiny; if it is dull and black, you can clean it with a commutator cleaning stone. Clean Dirty Figure-38 Figure-39 17. To clean the commutator, press the commutator cleaning stone against the commutator and rotate the armature by turning the spindle shaft by hand. Continue for a minute or until commutator is clean and shiny. Figure-40 18. Reconnect the power wire, ensuring that the wire path is correct.

ALPHA® VSP-230 SCHEMATIC Revised: 01/2008 27

ALPHA® VSP-230 PARTS LIST DRAWING NO. PART NO.

ALPHA® VSP-230 PARTS LIST DRAWING NO. PART NO. DESCRIPTION QUANTITY 35 210035 O-Ring 21.2x1.8 1 36 210036 Ball Bearing 608 1 37 210081 Armature 230V 1 38 210038 Ball Bearing 607 1 39 210039 Rubber Bearing Seat 1 40 210040 Windshield 1 41 210041 Self-tapping screw 4.

ALPHA® VSP-230 PARTS LIST DRAWING NO. PART NO. DESCRIPTION QUANTITY 70 210070 Switch Push Lever 1 71 210071 Switch Push Button 1 72 210086 GFCI 230V (European) 1 73 210073 Wrench 2 74 210074 Side Handle 1 75 210075 O-Ring 15x2.65 1 76 210076 Dash Panel 1 77 210077 Self-tapping screw 4.2x40 2 78 210078 Self-tapping screw 4.

ALPHA® TOOL REPAIR SERVICE For more information concerning Alpha® tool repair service, please contact the Alpha® repair centers listed below: COMPANY HEADQUARTERS: Alpha Professional Tools® 103 Bauer Drive Oakland, NJ 07436 Hours of Operation: 8:30 a.m. – 5:00 p.m. EST Telephone Number: 201-337-3343 Toll-Free Number: 800-648-7229 FACTORY SERVICE AND TRAINING CENTER: 3625 W. Teco Ave., Suite #5 Las Vegas, NV 89118 Hours of Operation: 7:30 a.m. – 4:00 p.m.

EC DECLARATION OF CONFORMITY Name of Manufacturer: Alpha Professional Tools ® Address of Manufacturer: 103 Bauer Drive Oakland, NJ 07436 USA Herewith declares that: ELECTRIC HAND TOOL: Make: Type: “Alpha® Wet Polisher” Alpha Professional Tools ® VSP-230 -Does comply with the provisions of the Mechanism Directive 2006/42/EC and EMC Directive 2004/108/EC including the subsequent amendments.

APPENDIX A FREQUENTLY ASKED QUESTIONS Q. What applications is the Alpha® VSP-230 recommended for? A. The Alpha® VSP-230 is recommended for wet polishing, wet core drilling, profiling and grinding. Q. What is the warranty for this VSP-230? A. Alpha Professional Tools® warranties the VSP-230 against defects in material and workmanship for a period of 180 days from the date of original retail purchase (proof of purchase required).

A. Contact the dealer where you purchased the tool or Alpha Professional Tools® directly at 800-648-7229. Q. Can I use my VSP-230 as a wet cutting tool with a diamond blade? A. No. The VSP-230 only has a 2,800 no load RPM rating. This is not enough RPM for cutting applications with a diamond blade. It is unsafe to use the VSP-230 as a cutting tool. Do not attempt to cut with the VSP-230. Q. Can I use my VSP-230 for dry polishing applications? A. No. The VSP-230 is designed for wet use only.

PRODUCT REGISTRATION CARD Model No. Serial No.

103 Bauer Drive, Oakland, NJ 07436 • 800-648-7229 • Fax: 800-286-0114 www.alpha-tools.com Copyright © 2008 Alpha Professional Tools. All rights reserved.