Instructions

Program examples

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany · Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

91

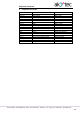

Fig. 10.3

10.2 Task 2: Mixer control

The task is to implement an industrial mixer with simple control functions.

Task definition:

1. Automatic and Manual operation modes are required. The switch SA1 “MODE” is in-

stalled to switch between the modes.

2. In Automatic mode the operating cycle can be started with the button SB1 “START”

and stopped automatically with the end of the cycle or manually with the button SB2

“STOP”. The cycle duration is 5 minutes. During the cycle the motor of the mixer is on

for 15 seconds and off for 10 seconds alternately. All settings can be changed in the

program.

3. In Manual mode the motor can be started with the button SB1 “START” and stopped

with the button SB2 “STOP”.

4. When the motor is overloaded (overload switch F1), it should be switched off auto-

matically, an intermittent acoustic warning signal (HA1) with the 3-second interval

should be produced and an operating error should be indicated by the signal lamp

HL1 "Overload".

5. The acoustic signal can be switched off with the button SB3 “RESET”.

6. The button SB4 “CONTROL” is used for the functional test of the lamp HL1 and the

acoustic signal HA1.

Device selection:

The control device must have minimum 6 digital inputs and 3 digital outputs to implement

this task. These features can be provided by devices of PR110 series.

The task implementation with the device PR110-24.8D.4R: