Product Specifications

PRODUCT SPECIFICATIONS Gas Furnace: G80CTL

6 441 51 3500 01

Specifications subject to change without notice.

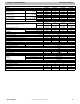

DOWNFLOW VENT CONFIGURATIONS

SEE NOTES: 1,2,4,5,7,8,9

A02061

SEE NOTES: 1,2,4,5,6,7,8,9

A02062

SEE NOTES: 1,2,3,4,5,7,8,9 A02063

DOWNFLOW CONTINUTED UPFLOW VENT CONFIGURATIONS

SEE NOTES:1,2,3,4,5,7,8,9 A02060

A02058SEE NOTES: 1,2,4,7,8,9

SEE NOTES: 1,2,3,4,7,8,9

A02059

HORIZONTAL RIGHT VENT CONFIGURATIONS

SEE NOTES: 1,2,4,5,7,8,9

A02070

SEE NOTES: 1,2,4,5,7,8,9 A02068

SEE NOTES: 1,2,4,7,8,9

A02069

HORIZONTAL LEFT VENT CONFIGURATIONS

SEE NOTES: 1,2,4,7,8,9

A02064

SEE NOTES: 1,2,4,5,7,8,9

A02065

SEE NOTES: 1,2,4,5,7,8,9

A02066

HORIZONTAL LEFT VENT CONFIGURATIONS

SEE NOTES: 1,2,4,5,7,8,9

A02067

Venting Notes

1. For common vent, vent connector sizing and vent material: United States−use the NFGC.

2. Immediately increase to 5 inch (102 mm) or 6 inch (152 mm) vent connector outside furnace

casing when 5 inch (127 mm) vent connector is required, refer to Note 1 above.

3. Side outlet vent for upflow and downflow installations must use Type B vent immediately af-

ter exiting the furnace, expect when Downflow Vent Guard Kit is used in the downflow posi-

tion.

4. Type−B vent where required, refer to Note 1 above.

5. A 4 inch(102 mm) single−wall (26 ga. min.) vent must be used inside furnace casing and

when the NAHB00301VC Downflow Vent Guard Kit is used external to the furnace.

6. Accessory Downflow Vent Guard Kit is required in downflow installations with lower vent

configuration.

7. Chimney Adapter Kit may be required for exterior masonry chimney applications. Refer to

Chimney Adapter Kit for sizing and complete application details.

8. Secure vent connector to furnace elbow with (2) corrosion−resistant sheet metal screws,

spaced approximately 180_ apart.

9. Secure all other single wall vent connector joints with (3) corrosion resistant screws spaced

approximately 120_ apart. Secure Type−B vent connectors per vent connector manufactur-

er’s recommendations.