User's Manual

Table Of Contents

- Agilent Technologies 16750A/B Logic Analyzer

- Agilent Technologies 16750A/B Logic Analyzer

- Contents

- Getting Started

- Step 1. Connect the logic analyzer to the device under test

- Step 2. Choose the sampling mode

- Step 3. Format labels for the probed signals

- Step 4. Define the trigger condition

- Step 5. Run the measurement

- Step 6. Display the captured data

- For More Information...

- Example: Timing measurement on counter board

- Example: State measurement on counter board

- Task Guide

- Probing the Device Under Test

- Choosing the Sampling Mode

- To select transitional timing or store qualified

- Formatting Labels for Logic Analyzer Probes

- Setting Up Triggers and Running Measurements

- Displaying Captured Data

- Using Symbols

- Printing/Exporting Captured Data

- Cross-Triggering

- Solving Logic Analysis Problems

- Saving and Loading Logic Analyzer Configurations

- Reference

- The Sampling Tab

- The Format Tab

- Importing Netlist and ASCII Files

- The Trigger Tab

- The Symbols Tab

- Error Messages

- Must assign Pod 1 on the master card to specify actions for flags

- Branch expression is too complex

- Cannot specify range on label with clock bits that span pod pairs

- Counter value checked as an event, but no increment action specified

- Goto action specifies an undefined level

- Maximum of 32 Channels Per Label

- Hardware Initialization Failed

- Must assign another pod pair to specify actions for flags

- No more Edge/Glitch resources available for this pod pair

- No more Pattern resources available for this pod pair

- No Trigger action found in the trace specification

- Slow or Missing Clock

- Timer value checked as an event, but no start action specified

- Trigger function initialization failure

- Trigger inhibited during timing prestore

- Trigger Specification is too complex

- Waiting for Trigger

- Analyzer armed from another module contains no "Arm in from IMB" event

- Specifications and Characteristics

- Concepts

- Understanding Logic Analyzer Triggering

- Understanding State Mode Sampling Positions

- Getting Started

- Glossary

- Index

39

Chapter 2: Task Guide

To select transitional timing or store qualified

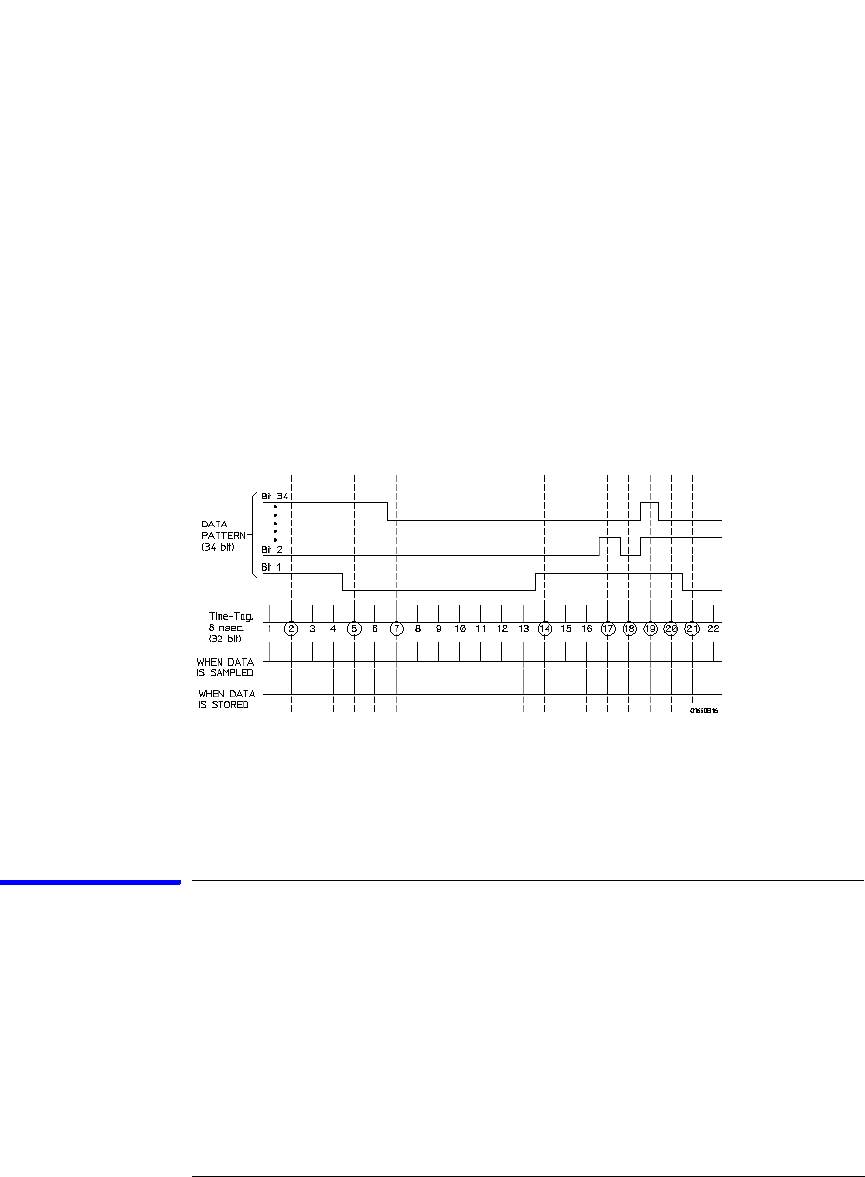

happen at this rate, two samples are stored (four at the fastest rate of

2.5 ns) for every transition. Therefore, with 2 K samples of memory, 1

K of transitions are stored. You must subtract one, which is necessary

for a starting point, for a minimum of 1023 stored transitions.

Maximum Transitions Stored

If transitions occur at a fast rate, such that there is a transition at each

sample point, only one sample is stored for each transition as shown by

time tags 17 through 21 below. If this continues for the entire trace, the

number of transitions stored is 2 K samples. Again, you must subtract

the starting point sample, which then yields a maximum of 2047 stored

transitions.

In most cases a transitional timing trace is stored by a mixture of the

minimum and maximum cases. Therefore, in this example the actual

number of transitions stored will be between 1023 and 2047.

Transitional Timing Considerations

Data Storage

When an edge is detected, two samples (four when sampling at 2.5 ns)

are stored across all channels assigned to the timing analyzer. The need

of two samples is to avoid loss of data if a second edge were to occur to

soon after the first edge for the edge detectors to reset.