User`s guide

M3000A/M3046A/M3015A/M3016A Service Guide

Troubleshooting the Instrument 5-25

Part 3 Using Support Functions

There are various support functions available in the monitor to assist in fault diagnosis. These

are desribed below. If diagnostic and error information is to be communicated to Agilent

Technologies, this should always associated with a particular instrument by means of the

serial number. The serial numbers for the Monitor and the Measurement Server can be seen

in the “Revisions” window (press Setup key then select “Revisions”). However, if a

Measurement Server Extension (M3015A or M3016A) is in use, the number will not appear

and must be noted down from the back of the Extension. To do this, remove the Measurement

Server and Extension from the Monitor, so that the back of the extension is visible.

7KH6WDWXV/RJDQG(UURU&RGHV

One possible line of fault isolation is in the HUURUFRGHV. However, some error codes cannot

provide diagnostic information at the repair site and must be analyzed in the factory if they

appear repeatedly. Whenever one of the subsystems is unable to perform an operation, an

error code is generated. Error codes are assigned to fatal and non-fatal errors.

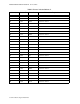

Error codes can be found in the 6WDWXV/RJ while in the operating modes. In the

Configuration, Demonstration, and Monitoring modes, the Status Log only displays fatal

error codes. In the Service Mode, the Status Log displays both fatal and non-fatal error codes

with a blank line separating the two.

Errors that occur during start-up or regular monitoring are logged in the Status Log. The

Status Log can be printed and cleared. If fatal errors occur repeatedly, send a printout of the

Status Log (Service Mode) to Agilent Technologies.

There are two categories of error:

)DWDO(UURUV²These errors indicate major problems that cause the Monitor to reset and re-

start. These types of errors might force the Monitor to go back to user defaults. Fatal errors

usually point to a defective System Board. This will be reported to the user by the INOP

alarm: CHECK STATUS LOG. The fatal error can be reviewed in the Status Log menu.

After the Status Log is reviewed, the INOP is removed.

If a fatal error occurs which cannot be diagnosed, download the Staus Log into a file using

the M3 Support Tool and send it to the Technical Marketing department at Agilent

Technologies.

1RQ)DWDO(UURUV²These indicate general errors that are not significant enough to affect

normal Monitor operation. Non-fatal errors are errors that give some hints about an

unexpected behavior of the system but that are not relevant to correct system function. They

do not cause the Instrument to reset or restart. They are not reported during monitoring but

can be seen in the Status Log if the Monitor is in Service Mode.

Monitor, Measurement Server and Measurement Server Extension errors are reported

separately in the Status Log.