User`s guide

Table Of Contents

- Title Page

- Contents

- Getting Started

- Introduction and Measurement

- Phase Noise Basics

- Expanding Your Measurement Experience

- Starting the Measurement Software

- Using the Asset Manager

- Using the Server Hardware Connections to Specify the Source

- Setting GPIB Addresses

- Testing the 8663A Internal/External 10 MHz

- Testing the 8644B Internal/External 10 MHz

- Viewing Markers

- Omitting Spurs

- Displaying the Parameter Summary

- Exporting Measurement Results

- Absolute Measurement Fundamentals

- Absolute Measurement Examples

- Residual Measurement Fundamentals

- What is Residual Noise?

- Assumptions about Residual Phase Noise Measurements

- Calibrating the Measurement

- Measurement Difficulties

- Residual Measurement Examples

- FM Discriminator Fundamentals

- FM Discriminator Measurement Examples

- AM Noise Measurement Fundamentals

- AM Noise Measurement Examples

- Baseband Noise Measurement Examples

- Evaluating Your Measurement Results

- Advanced Software Features

- Reference Graphs and Tables

- Approximate System Noise Floor vs. R Port Signal Level

- Phase Noise Floor and Region of Validity

- Phase Noise Level of Various Agilent Sources

- Increase in Measured Noise as Ref Source Approaches DUT Noise

- Approximate Sensitivity of Delay Line Discriminator

- AM Calibration

- Voltage Controlled Source Tuning Requirements

- Tune Range of VCO for Center Voltage

- Peak Tuning Range Required by Noise Level

- Phase Lock Loop Bandwidth vs. Peak Tuning Range

- Noise Floor Limits Due to Peak Tuning Range

- Tuning Characteristics of Various VCO Source Options

- 8643A Frequency Limits

- 8644B Frequency Limits

- 8664A Frequency Limits

- 8665A Frequency Limits

- 8665B Frequency Limits

- System Specifications

- System Interconnections

- PC Components Installation

- Overview

- Step 1: Uninstall the current version of Agilent Technologies IO libraries

- Step 2: Uninstall all National Instruments products.

- Step 3: Install the National Instruments VXI software.

- Step 4: Install the National Instruments VISA runtime.

- Step 5: Install software for the NI Data Acquisition Software.

- Step 6: Hardware Installation

- Step 7. Finalize National Instruments Software Installation.

- Step 8: System Interconnections

- Step 9: Install Microsoft Visual C++ 2008 Redistributable Package use default settings

- Step 10: Install the Agilent I/O Libraries

- Step 11: Install the E5500 Phase Noise Measurement software.

- Step 12: Asset Configuration

- Step 13: License Key for the Phase Noise Test Set

- Overview

- PC Digitizer Performance Verification

- Preventive Maintenance

- Service, Support, and Safety Information

- Safety and Regulatory Information

- Safety summary

- Equipment Installation

- Environmental conditions

- Before applying power

- Ground the instrument or system

- Fuses and Circuit Breakers

- Maintenance

- Safety symbols and instrument markings

- Regulatory Compliance

- Declaration of Conformity

- Compliance with German noise requirements

- Compliance with Canadian EMC requirements

- Service and Support

- Return Procedure

- Safety and Regulatory Information

Residual Measurement Fundamentals

7

Agilent E5505A User’s Guide 209

Calibration and measurement guidelines

The following general guidelines should be considered when setting up and

making a residual two-port phase noise measurement.

1

For residual phase noise measurements, the source noise must be

correlated.

a

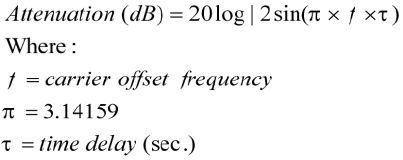

The phase delay difference in the paths between the power splitter and

the phase detector must be kept to a minimum when making residual

noise measurements. In other words, by keeping the cables between the

phase detector and power splitter short,

τ will be small. The attenuation

of the source noise is a function of the carrier offset frequency, and the

delay time

(τ) and is equal to:

b

The source should also have a good broadband phase noise floor because

at sufficiently large carrier offsets it will tend to decorrelate when

measuring components with large delays. At , source noise is

rejected completely. the first null in noise can be used to determine the

delay difference. At , source noise shows up unattenuated. At

lower offsets, source noise is attenuated at 20 dB per decade rate at 0.1

of , source noise is attenuated 20 dB. Examples of sources which best

meet these requirements are the 8644B and 8642A/B.

The source used for making residual phase noise measurements must be low in

AM noise because source AM noise can cause AM to

ΦM conversion in the DUT.

Mixer-type phase detectors only provide about 20 to 30 dB of rejection to AM

noise in a

ΦM noise measurement so the AM noise can appear in the phase

noise plot

.

2

It is very important that all components in the test setup be well shielded

from RFI. Unwanted RF coupling between components will make a

measurement setup very vulnerable to external electric fields around it.

The result may well be a setup going out of quadrature simply by people

moving around in the test setup area and altering surrounding electric

fields. A loss of quadrature stops the measurement.

3

When making low-level measurements, the best results will be obtained

from uncluttered setups. Soft foam rubber is very useful for isolating the

DUT and other phase-sensitive components from mechanically-induced

phase noise. The mechanical shock of bumping the test set or kicking the

f

1

τ

---

=

f

1

2

π

τ

----------

=

1

2

π

τ

----------