Owner manual

APPENDIX G: PIPING DRAWINGS

PR2: 05/09/12 Page 137 of 152

Benchmark 1.5LN Low NOx Boiler

Operation and Maintenance Manual

OMM-0041_0D

GF-120

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

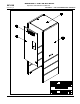

* CONDENSATE

DRAIN TRAP

1-1/2" NPT

DRAIN CONN.

BACKFLOW PREVENTER

DIAPHRAGM TYPE

EXPANSION TANK

LINE

SIZE

BYPASS

SUPPLY

WATER

HEATING

SYSTEM

SUPPLY

PRESSURE

REDUCING

FILL VALVE

P&T

SYSTEM

PUMP

CHECK

VALVE

(TYP.)

AUTOMATIC

AIR VENT

AIR

SEPARATOR

GAS SUPPLY

HEATING

SYSTEM

RETURN

* 1-1/2" MANUAL

SHUTOFF

VALVE

P&T

RELIEF

VALVE (TYP.)

P&T

5) THIS IS A TYPICAL INSTALLATION DRAWING. LOCAL CODES AND AUTHORITIES SHOULD BE CONSULTED.

FITTINGS TO PREVENT INTERFERENCE WITH REMOVAL OF BOILER PANELS AND COVERS. ALL PIPING AND

ELECTRIC CONNECTIONS (SERVICE SWITCHES, CONDUIT BOXES) SHOULD LIKEWISE BE 6" AWAY FROM SIDE PANELS.

4) LOCATE WATER INLET AND OUTLET FITTINGS (i.e. UNIONS, ELBOWS, ETC.) A MINIMUM OF 6'' FROM BOILER

CONVENIENT FLOOR DRAIN. RELIEF VALVE SHOULD BE PIPED VERTICALLY TO A HEIGHT 18'' ABOVE FLOOR.

1) FOR ACTUAL SIZES AND LOCATIONS OF PIPING AND OTHER CONNECTIONS TO THE BOILER, SEE DIMENSIONAL DRAWING (AP-A-739).

3) ALL (*) ITEMS ARE INCLUDED SEPARATELY IN SHIPMENT FROM FACTORY.

2) SHELL DRAIN VALVE AND CONDENSATE DRAIN TRAP SHOULD BE ARRANGED TO PERMIT THE FLUIDS TO DRAIN FREELY, BY GRAVITY, TO A

NOTES:

DATE

DATE

AERCO

BENCHMARK 1.5 MIL. BTU LOW NOx

GAS FIRED MULTIPLE BOILERS

WITH ZERO SIDE CLEARANCE INSTALLATION

APPD.

DWN.BY

SCALE

JK

NTS

NORTHVALE, NJ 07647

INTERNATIONAL, INC.

102307

SD-A-737

TEMPERATURE GAUGE

P&T

PRESSURE &

ISOLATION VALVE

UNION

Y STRAINER

LEGEND

BALANCING VALVE

REV

C

6) WHEN AVAILABLE GAS PRESSURE IS GREATER THAN 2.0 PSIG, A LOCK-UP STYLE REGULATOR MUST BE INSTALLED

DOWNSTREAM OF THE 2" MANUAL SHUTOFF VALVE TO BRING THE GAS PRESSURE DOWN TO 2.0 PSIG.

7) A GAS REGULATOR IS MANDATORY FOR THE STATE OF MASSACHUSETTS, REGARDLESS OF SUPPLY PRESSURE.

SEE DIAGRAM 1

DRIP TRAP

* 1-1/2" MANUAL

SHUTOFF

VALVE

MAINTAIN A REGULATED

4.0" W.C. (FM), 4.2 W.C. (IRI)

GAS PRESSURE AT MAX

BTU/HR INPUT

GAS SUPPLY

(TO BOILER)

(SEE NOTE 7)

Diagram 1

AT MAXIMUM BTU/HR INPUT,

MAINTAIN MINIMUM GAS PRESSURE AT

4.0" W.C.(FM GAS TRAIN); 4.2" W.C. (IRI).

MAX. GAS PRESSURE = 2.0 PSIG. (SEE NOTE 6)

DRIP TRAP

P&T

P&T