User Manual

Table Of Contents

- VUE Key Layout

- VUE Soft keys

- Single Axis VUE Tool, and Datum keys

- Readout Parameter Access Code

- Access to Machine Parameter Operations

- Introduction

- Software Version

- VUE

- Symbols within Notes

- VUE Fonts

- Warranty

- Warranty Information:

- I – 1 Fundamentals of Positioning

- Datums

- Actual Position, Nominal Position, and Distance-To-Go

- Absolute Workpiece Positions

- Incremental workpiece positions

- Zero Angle Reference Axis

- Reading head position

- Encoder Reference Marks

- I – 2 General Operations for VUE

- Screen Layout

- VUE Hard Keys

- Power Up

- Reference Mark Evaluation

- Working without reference mark evaluation

- ENABLE/DISABLE REF function

- Operating Modes

- Setup

- Job Setup Parameters

- Units

- Scale Factor

- Mirror

- Diameter Axes

- Near Zero Warning

- Status Bar Settings

- Job Clock

- Console Adjustment

- Language

- Import/Export

- Set/Zero Soft Key

- I – 3 Milling Specific Operations

- Key Functions Detailed

- Tool Hard Key

- Tool Table

- Import/Export

- Tool Radius Compensation feature

- Sign for the length difference DL

- Calling the Tool from the Tool Table

- Datum Setting

- Datum Setting with a Tool

- Presets

- Absolute Distance Preset

- Preparation:

- Incremental Distance Preset

- 1/2 Hard Key

- Circle, and Linear Pattern

- Functions for milling pattern soft keys

- Circle pattern

- Linear Pattern

- Incline & Arc Milling

- Incline Milling

- Arc Milling

- I – 4 Turning Specific Operations

- Key Functions Detailed

- Tool Table

- Tool Display Icon

- Setting Tool Offsets with Tool/Set

- Import/Export

- Setting Tool Offsets with Lock Axis Function

- Calling a Tool from the Tool Table

- Datum Setting

- Setting Datums using LOCK AXIS Function

- Taper Calculator Hard Key

- Presets

- Radius/Diameter Soft Key

- Vectoring

- Coupling

- Z Coupling (turning applications only)

- Enabling Z Coupling

- Disabling Z Coupling

- II – 1 Installation Setup

- Installation Setup Parameters

- Exporting the current Installation Setup:

- Importing a new Tool Table

- Encoder Setup

- Display Configuration

- Error Compensation

- Linear Error Compensation

- Non-Linear Error Compensation

- Starting a Non-linear Error Compensation Table

- Configuring the Compensation Table

- Reading the Graph

- Viewing the Compensation Table

- Exporting the Current Compensation Table

- Importing a New Compensation Table

- Backlash Compensation

- Counter Settings

- Diagnostics

- Keypad Test

- Display Test

- II – 2 Installation and Electrical Connections

- Installation

- Electrical requirements

- Environmental

- Preventative maintenance

- II – 3 Dimensions

- Overview

- Accessory ID Number

34 I

I – 4 Turning Specific Operations

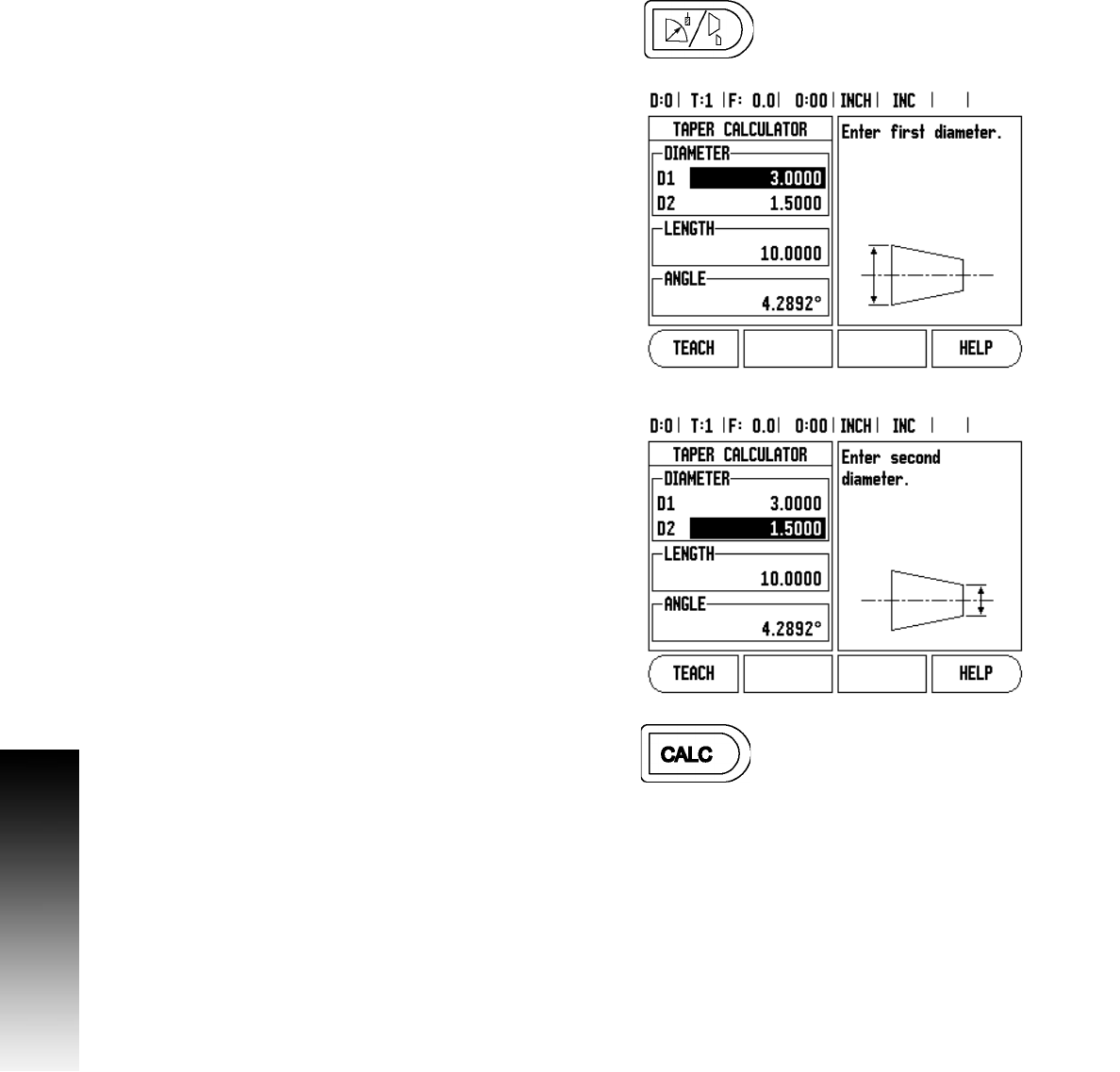

Taper Calculator Hard Key

Use the taper calculator to caculate taper angle.

Calculate tapers either by entering dimensions from a print, or by

touching a tapered workpiece with a tool, or indicator.

Entry values:

For the taper ratio, calculation requires:

Length of the taper

Change in the radius of the taper.

For taper calculation using both diameters (D1, D2), and length

requires:

Starting diameter

End diameter

Length of the taper

Using Taper Calculator

8 Press the CALC hard key: The soft key selection now changes to

include the taper calculator funtions.

8 To calculate the taper angle using two diameters, and length

between, press the taper: di/D2/l soft keys.

8 First taper point, diameter 1, either enter a point using the numeic

keys, and press enter, or touch the tool to one point, and press

note.

8 Repeat this for the diameter 2 field. When using the NOTE key, the

taper angle is automatically calculated. When entering data

numerically, enter data into the length field, and press ENTER: The

taper angle will appear in the angle field.

8 To calculate angles using the ratio of the diameter, change to length,

and press the taper: RATIO soft key.

8 Using the numeric keys, enter data into the ENTRY 1, and ENTRY 2

fields.

8 Press ENTER after each selection: The calculated ratio, and the

angle will appear in their respective fields.