User Manual

Table Of Contents

- VUE Key Layout

- VUE Soft keys

- Single Axis VUE Tool, and Datum keys

- Readout Parameter Access Code

- Access to Machine Parameter Operations

- Introduction

- Software Version

- VUE

- Symbols within Notes

- VUE Fonts

- Warranty

- Warranty Information:

- I – 1 Fundamentals of Positioning

- Datums

- Actual Position, Nominal Position, and Distance-To-Go

- Absolute Workpiece Positions

- Incremental workpiece positions

- Zero Angle Reference Axis

- Reading head position

- Encoder Reference Marks

- I – 2 General Operations for VUE

- Screen Layout

- VUE Hard Keys

- Power Up

- Reference Mark Evaluation

- Working without reference mark evaluation

- ENABLE/DISABLE REF function

- Operating Modes

- Setup

- Job Setup Parameters

- Units

- Scale Factor

- Mirror

- Diameter Axes

- Near Zero Warning

- Status Bar Settings

- Job Clock

- Console Adjustment

- Language

- Import/Export

- Set/Zero Soft Key

- I – 3 Milling Specific Operations

- Key Functions Detailed

- Tool Hard Key

- Tool Table

- Import/Export

- Tool Radius Compensation feature

- Sign for the length difference DL

- Calling the Tool from the Tool Table

- Datum Setting

- Datum Setting with a Tool

- Presets

- Absolute Distance Preset

- Preparation:

- Incremental Distance Preset

- 1/2 Hard Key

- Circle, and Linear Pattern

- Functions for milling pattern soft keys

- Circle pattern

- Linear Pattern

- Incline & Arc Milling

- Incline Milling

- Arc Milling

- I – 4 Turning Specific Operations

- Key Functions Detailed

- Tool Table

- Tool Display Icon

- Setting Tool Offsets with Tool/Set

- Import/Export

- Setting Tool Offsets with Lock Axis Function

- Calling a Tool from the Tool Table

- Datum Setting

- Setting Datums using LOCK AXIS Function

- Taper Calculator Hard Key

- Presets

- Radius/Diameter Soft Key

- Vectoring

- Coupling

- Z Coupling (turning applications only)

- Enabling Z Coupling

- Disabling Z Coupling

- II – 1 Installation Setup

- Installation Setup Parameters

- Exporting the current Installation Setup:

- Importing a new Tool Table

- Encoder Setup

- Display Configuration

- Error Compensation

- Linear Error Compensation

- Non-Linear Error Compensation

- Starting a Non-linear Error Compensation Table

- Configuring the Compensation Table

- Reading the Graph

- Viewing the Compensation Table

- Exporting the Current Compensation Table

- Importing a New Compensation Table

- Backlash Compensation

- Counter Settings

- Diagnostics

- Keypad Test

- Display Test

- II – 2 Installation and Electrical Connections

- Installation

- Electrical requirements

- Environmental

- Preventative maintenance

- II – 3 Dimensions

- Overview

- Accessory ID Number

VUE 23

I – 3 Milling Specific Operations

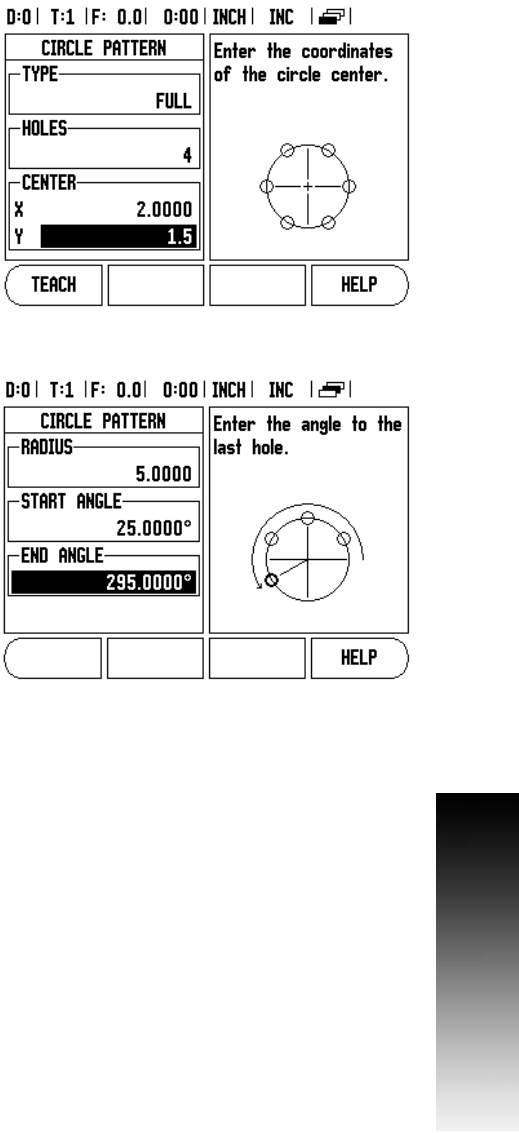

Circle pattern

Example: Enter data, and execute a circle pattern.

Holes (no. of): 4

Coordinates of center: X = 2.0” / Y = 1.5”

Bolt circle radius: 5

Start angle: Angle between X axis, and first hole: 25°

Hole depth: Z = -0.25”

1st step: Enter data

8 Press CIRCLE PATTERN hard key.

8 Enter the type of circle pattern (full). Cursor to the next field.

8 Enter the number of holes (4).

8 Enter the X, and Y coordinates of the circle center (X=2.0), (Y=1.5).

Cursor to the next field.

8 Enter the radius of the circle pattern (5).

8 Enter the start angle (25°).

8 Enter the end angle (295°) (this can only be changed if entering a

“segment”). The End Angle is defined as the angle from the positive

X-axis to the end of the pattern.

8 Enter the depth when needed. The depth of the hole is optional, and

may be left blank. If not required, press ENTER.

8 Three views are available: Incremental DRO, Pattern Graphic, and

Absolute DRO. Press the VIEW soft key to toggle through the

available screens.

2nd step: Drill

8 Move to hole:

8 Traverse the X, and Y axes until display value zero.

8 Drill:

8 Traverse to display value zero in the tool axis. After drilling, retract

the drill in tool axis.

8 Press the NEXT HOLE soft key.

8 Continue to drill the remaining holes in the same way.

8 When the pattern is complete, press the END soft key.