User Manual

Table Of Contents

- VUE Key Layout

- VUE Soft keys

- Single Axis VUE Tool, and Datum keys

- Readout Parameter Access Code

- Access to Machine Parameter Operations

- Introduction

- Software Version

- VUE

- Symbols within Notes

- VUE Fonts

- Warranty

- Warranty Information:

- I – 1 Fundamentals of Positioning

- Datums

- Actual Position, Nominal Position, and Distance-To-Go

- Absolute Workpiece Positions

- Incremental workpiece positions

- Zero Angle Reference Axis

- Reading head position

- Encoder Reference Marks

- I – 2 General Operations for VUE

- Screen Layout

- VUE Hard Keys

- Power Up

- Reference Mark Evaluation

- Working without reference mark evaluation

- ENABLE/DISABLE REF function

- Operating Modes

- Setup

- Job Setup Parameters

- Units

- Scale Factor

- Mirror

- Diameter Axes

- Near Zero Warning

- Status Bar Settings

- Job Clock

- Console Adjustment

- Language

- Import/Export

- Set/Zero Soft Key

- I – 3 Milling Specific Operations

- Key Functions Detailed

- Tool Hard Key

- Tool Table

- Import/Export

- Tool Radius Compensation feature

- Sign for the length difference DL

- Calling the Tool from the Tool Table

- Datum Setting

- Datum Setting with a Tool

- Presets

- Absolute Distance Preset

- Preparation:

- Incremental Distance Preset

- 1/2 Hard Key

- Circle, and Linear Pattern

- Functions for milling pattern soft keys

- Circle pattern

- Linear Pattern

- Incline & Arc Milling

- Incline Milling

- Arc Milling

- I – 4 Turning Specific Operations

- Key Functions Detailed

- Tool Table

- Tool Display Icon

- Setting Tool Offsets with Tool/Set

- Import/Export

- Setting Tool Offsets with Lock Axis Function

- Calling a Tool from the Tool Table

- Datum Setting

- Setting Datums using LOCK AXIS Function

- Taper Calculator Hard Key

- Presets

- Radius/Diameter Soft Key

- Vectoring

- Coupling

- Z Coupling (turning applications only)

- Enabling Z Coupling

- Disabling Z Coupling

- II – 1 Installation Setup

- Installation Setup Parameters

- Exporting the current Installation Setup:

- Importing a new Tool Table

- Encoder Setup

- Display Configuration

- Error Compensation

- Linear Error Compensation

- Non-Linear Error Compensation

- Starting a Non-linear Error Compensation Table

- Configuring the Compensation Table

- Reading the Graph

- Viewing the Compensation Table

- Exporting the Current Compensation Table

- Importing a New Compensation Table

- Backlash Compensation

- Counter Settings

- Diagnostics

- Keypad Test

- Display Test

- II – 2 Installation and Electrical Connections

- Installation

- Electrical requirements

- Environmental

- Preventative maintenance

- II – 3 Dimensions

- Overview

- Accessory ID Number

VUE 7

I – 2 General Operations for VUE

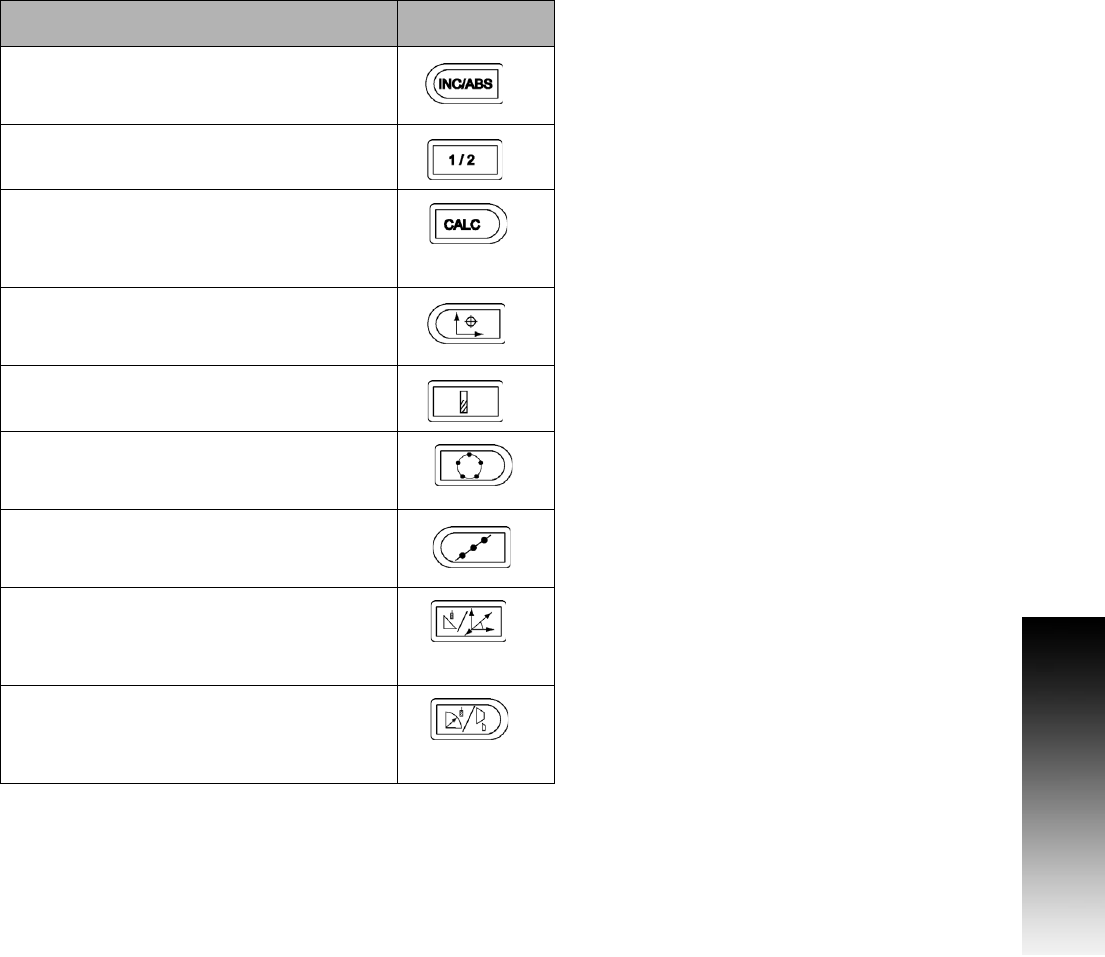

VUE Hard Keys

Hard keys on the VUE readouts vary depending on the number of axis

the readout includes. A one axis readout will only have the first three

hard keys shown below. A two, or three axis readout will have all the

hard keys shown below.

The last two keys are specific to a VUE readout that is either for

milling, or turning. The first symbol applies to a milling readout, and the

second symbol applies to a turning readout.

Hard Key function Hard Key

Symbol

Switches display between operating modes:

Distance-To-Go (Incremental) / Actual Value

(Absolute) (see page 10).

Used to divide the current position by two (see

page 22).

The CALC hard key opens the Calculator

functions for standard math, trigonometry,

RPM, and Taper (Turning only) functions (see

page 34).

The DATUM hard key opens the Datum form to

set the datum for each axis (for Milling see

page 17, for Turning see page 32).

The TOOL hard key opens the Tool Table (for

Milling see page 14, for Turning see page 30).

The CIRCLE PATTERN hard key (Mill only)

opens the Circle Pattern form. This calculates

the hole positions (see page 22).

The LINEAR PATTERN hard key (Mill only)

opens the Linear Pattern form. This calculates

the hole positions (see page 22).

The INCLINE MILLING hard key (Mill) /

VECTORING hard key (Turn) opens the Incline

milling forms (see page 25), or the Vectoring

form (see page 36).

The ARC MILLING hard key (Mill) / TAPER

CALC hard key (Turn) opens the Arc milling

forms (see page 25), or the Taper Calc form

(see page 34).