Manual

Table Of Contents

- Controls of the 3500i

- Manual Information

- Introduction

- Machining Fundamentals

- Manual Data Input

- Tool Management

- 4.1 Tool Table

- 4.2 Tool Data

- Program Management

- Conversational Editing

- Programming: Canned Cycles, sub-programs

- 7.1 Explaining Basic Cycles

- Round/Chamfer

- Rapid

- Line

- Arc

- Dwell:

- Plane Selection

- Reference Point Return:

- Fixture Offset (Work Coordinate System Select):

- Unit (Inch/MM)

- Dimension (Abs/Inc)

- Absolute Zero Set

- Block Form

- Temporary Path Tolerance

- System Data

- FeedRate

- FeedRate (4th-Axis)

- Spindle RPM

- M - Functions

- Tool Definition and Activation

- Repeat Blocks

- 7.2 Canned Cycles

- 7.3 Probing Cycles

- 7.4 Sub-programs

- 7.1 Explaining Basic Cycles

- Drawing Programs

- Running a Program on the Machine

- CAM: Programming

- 10.1 CAM Programming

- CAM Mode

- Recommended CAM Programming Sequence

- CAM Mode Mouse Operations

- CAM Mode Screen

- Activating CAM Mode

- Creating a New Program

- Tool Path Data Input

- Quick Coordinate Entry

- Job Setup: Basic tab

- Job Setup: Advanced tab

- Comment Tab

- Block Form: Basic tab

- Comment Tab

- Drilling Cycle:

- Drilling dialogue:

- Mill Cycle

- Pocket Cycle

- Pocket Finish Cycles

- Engraving Cycle

- Program Directive

- Modifying Toolbar

- Viewing Tools

- CAM Mode buttons

- CAM Setup

- Geometry

- DXF Import Feature

- Modifying Tools

- Shapes

- Tool Table

- Tool Paths

- CAM Example 1

- CAM Example 2

- 10.1 CAM Programming

- G-Code Edit, Help, & Advanced Features

- 11.1 G-Code Program Editing

- 11.2 G-Code and M-Code Definitions

- 11.3 Edit Help

- 11.4 Advanced Programming

- SPEED

- M - Functions

- Order of Execution

- Programming Non-modal Exact Stop:

- In-Position Mode (Exact Stop Check):

- Contouring Mode (Cutting Mode) :

- Setting Stroke Limit:

- Return from Reference Point:

- Move Reference from Machine Datum:

- Modifiers

- Block Separators

- Tool Offset Modification

- Expressions and Functions

- System Variables

- User Variables

- Variable Programming (Parametric Programming)

- Probe Move (G31)

- Conditional Statements

- Short Form Addressing

- Logical and Comparative Terms

- File Inclusion

- 11.5 Four Axis Programming

- Software Update

- Off-Line Software

20 1 Introduction

1.3 Main Operating Mode Screens

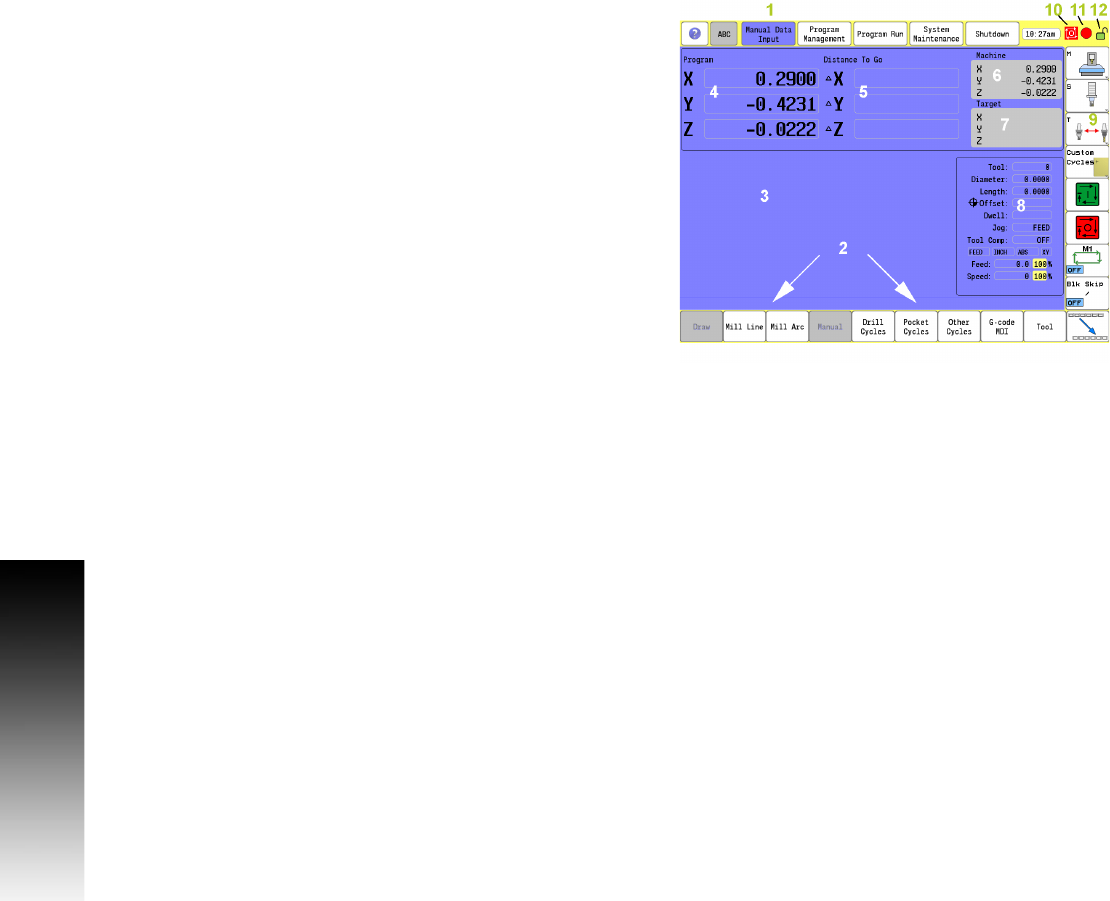

1.3 Main Operating Mode Screens

Display navigation

The three main operating modes: Manual Data Input, Program

Management, and Program Run each have there own screen. A

condensed description of these has been provided here on how to

navigate, become familiar with the information that is being provided.

Manual Data Input

The Manual Data Input screen (default screen), displays several

windows, and program buttons. The following list maps what is being

viewed on this screen. When the console is first turned on, the unit

defaults to this screen.

1 Manual Data Input (default screen).

2

Horizontal button Bar. These keys change to correspond with the

selected main mode display.

3 Display area / Preview Screen.

4

This displays the position of the machine during a program or

single event run.

5 This displays the Distance To Go per the program being run.

6

The Machine display window displays the actual position of the

machines axes.

7

The Target display window displays the position that the machine

is going to.

8 This displays the status of the machine during its current activity.

9

Machine function button; actual buttons displayed depend on the

features of your machine.

10

Program running status:

Red - Machine is idle.

Green - Program is running.

11

Message Indicator:

Yellow/Red (flashing): Error or Warning.

Green: All OK.

12 Screen Lock: The touch screen can be locked at any time.