Manual

Table Of Contents

- Controls of the 3500i

- Manual Information

- Introduction

- Machining Fundamentals

- Manual Data Input

- Tool Management

- 4.1 Tool Table

- 4.2 Tool Data

- Program Management

- Conversational Editing

- Programming: Canned Cycles, sub-programs

- 7.1 Explaining Basic Cycles

- Round/Chamfer

- Rapid

- Line

- Arc

- Dwell:

- Plane Selection

- Reference Point Return:

- Fixture Offset (Work Coordinate System Select):

- Unit (Inch/MM)

- Dimension (Abs/Inc)

- Absolute Zero Set

- Block Form

- Temporary Path Tolerance

- System Data

- FeedRate

- FeedRate (4th-Axis)

- Spindle RPM

- M - Functions

- Tool Definition and Activation

- Repeat Blocks

- 7.2 Canned Cycles

- 7.3 Probing Cycles

- 7.4 Sub-programs

- 7.1 Explaining Basic Cycles

- Drawing Programs

- Running a Program on the Machine

- CAM: Programming

- 10.1 CAM Programming

- CAM Mode

- Recommended CAM Programming Sequence

- CAM Mode Mouse Operations

- CAM Mode Screen

- Activating CAM Mode

- Creating a New Program

- Tool Path Data Input

- Quick Coordinate Entry

- Job Setup: Basic tab

- Job Setup: Advanced tab

- Comment Tab

- Block Form: Basic tab

- Comment Tab

- Drilling Cycle:

- Drilling dialogue:

- Mill Cycle

- Pocket Cycle

- Pocket Finish Cycles

- Engraving Cycle

- Program Directive

- Modifying Toolbar

- Viewing Tools

- CAM Mode buttons

- CAM Setup

- Geometry

- DXF Import Feature

- Modifying Tools

- Shapes

- Tool Table

- Tool Paths

- CAM Example 1

- CAM Example 2

- 10.1 CAM Programming

- G-Code Edit, Help, & Advanced Features

- 11.1 G-Code Program Editing

- 11.2 G-Code and M-Code Definitions

- 11.3 Edit Help

- 11.4 Advanced Programming

- SPEED

- M - Functions

- Order of Execution

- Programming Non-modal Exact Stop:

- In-Position Mode (Exact Stop Check):

- Contouring Mode (Cutting Mode) :

- Setting Stroke Limit:

- Return from Reference Point:

- Move Reference from Machine Datum:

- Modifiers

- Block Separators

- Tool Offset Modification

- Expressions and Functions

- System Variables

- User Variables

- Variable Programming (Parametric Programming)

- Probe Move (G31)

- Conditional Statements

- Short Form Addressing

- Logical and Comparative Terms

- File Inclusion

- 11.5 Four Axis Programming

- Software Update

- Off-Line Software

ACU-RITE 3500i 5

1.1 The 3500i

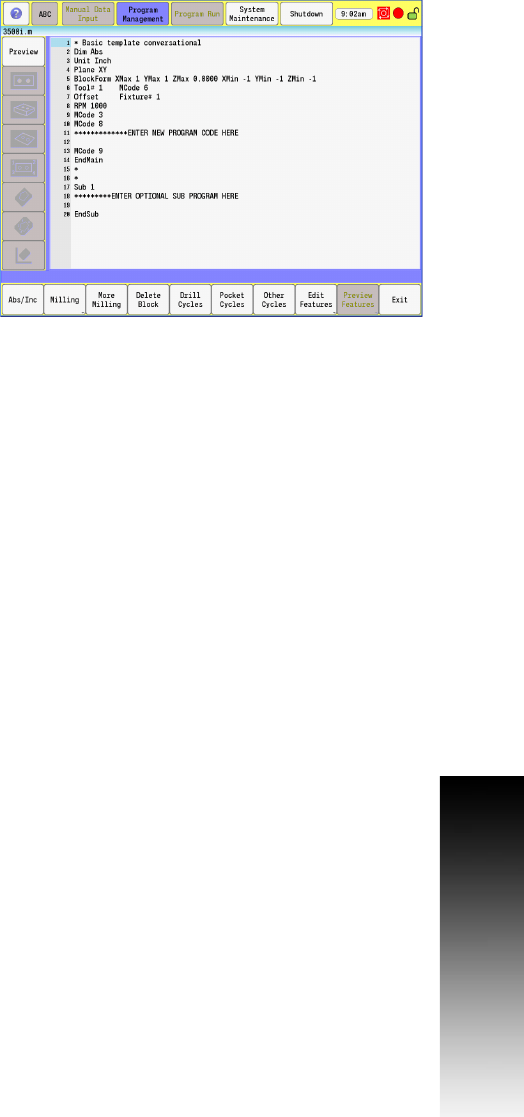

Writing Programs

The 3500i allows many features to be used without having to write a

program. But for operations that repeat or complex machining it is best

to write a program. Before you start to write a program, determine the

work-holding device and the location of Part Zero (the point to which

all movement is referenced). Since absolute positions are defined

from Part Zero, try to select a location that directly corresponds to

dimensions provided on the part print, such as the lower left corner of

the work. Then, you can develop a program using a procedure similar

to the one that follows:

The first block of a program is a safe starting position. This is where

the tool-change position (a location away from the work area where

the axes can return for safe tool changing) is input. The first block

includes the units of measurement (Inch/MM), mode of operation

(Absolute), move type (Rapid), and to cancel all auxiliary functions

(Tool Offsets, Spindle, and Coolant). This is the same as in g-code

(e.g. typical first blocks: G70, G90, G0, G28, Z0, & M5). Refer to

chapter 11 "G-Code on page 366”.

Subsequent blocks in the program set Spindle information, call Tool

number, turn on Coolant, and make the initial move toward the

work.

The remaining blocks in the program describe the required moves,

Canned Cycles, and Tool changes to complete the machining.

The next to the last block in the program returns the axes to the Tool

change position, turning off any auxiliary functions (Tool Offsets,

Spindle, and Coolant). The last block , EndMain, (M2) ends the

program. This is the same as in g-code (e.g. typical last blocks: M5,

G0, T0, X0, Y0, Z0, M9; M2). Refer to chapter 11 "M-Code List on

page 370”.

After writing a program, verify it. Run it in Draw Mode to troubleshoot

for errors. Verify that all programmed moves are safe, and accurate

to the part print dimensions.

Load the stock material into the selected work-holding device.

Set the Tool Offsets for each tool in the Tool Page.

Before running the part in the Auto Mode, run it in Single-Step Mode

to verify that both the program and the setting of Tool Offsets have

been correctly completed. Single-Step Mode allows you to execute

the program block-by-block.

After testing the program, make any necessary corrections.

When the finished program is ready for production, back it up on a

USB memory device.