User Guide

3M

™

Fastbond

™

Contact Adhesive 2000NF

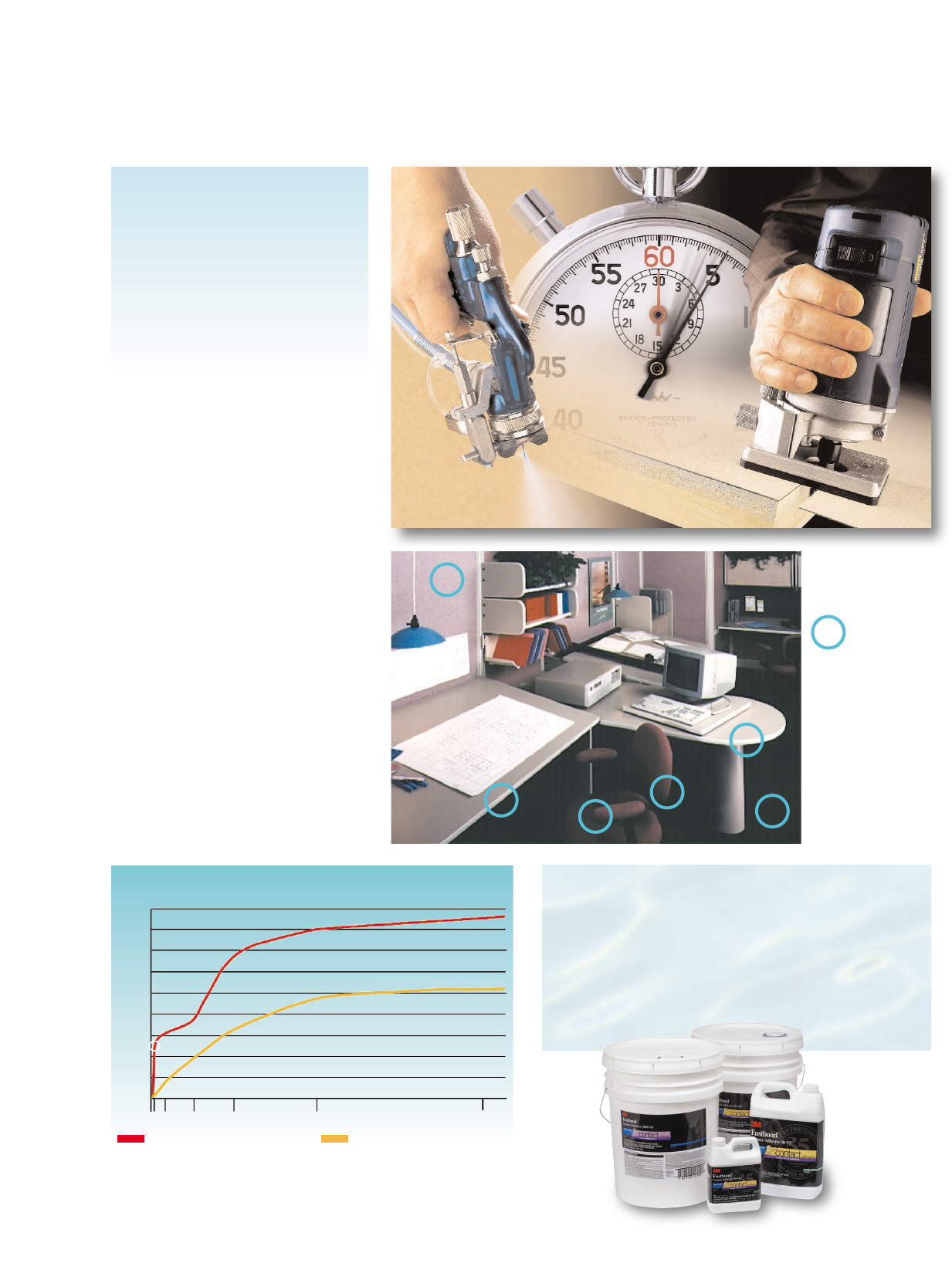

From spray to trim and post forming in seconds

• Bonding range up to 2 hours for

flexibility in speed of assembly

• Immediate handling strength for fast

throughput

• Ultimate shear strength of 350 psi

for reliability exceeding many

solvent-based adhesives

• High solids for more economical use

of adhesive (up to 3.5x more coverage

than a typical solvent-based product)

• Resistance to the temperatures found

in truck shipping and warehouses

• Two-part low pressure spray mixed

outside of nozzle to resist plugging

and help reduce overspray

• Heat activatable for fast post forming

Versatility to

bond plastic

laminate, plastics,

particle board,

plywood, flexible

urethane and latex

foams, partition

fabrics, carpeting,

painted metal, and

more throughout a

modular office.

After only one-minute, 3M

™

Fastbond

™

Contact Adhesive 2000NF

reaches 50 psi on a birch-to-birch overlap bond.

180

160

140

120

100

80

60

40

20

0

1

5

15

30 60 120

MINUTES

Fastbond 2000-NF Adhesive Conventional Water-based Contact Adhesive

3M

™

Fastbond

™

Contact Adhesive 2000NF Strength Build-up

(Lap Shear) Versus Conventional Water-based Contact Adhesive

PSI

NOTE: The values above are typical and should not be used for specification purposes. User should test for specific application suitability.

Benefits of neoprene adhesive

All 3M

™

Fastbond

™

Contact Adhesives are neoprene-

based for such characteristics as excellent resistance

to aging, rapid strength build-up, long bonding range,

excellent resistance to continuous load stress, and

good resistance to heat, water, and chemicals.

For applications ranging from

countertop lamination to marine carpet

bonding and interior automotive trim,

3M

™

Fastbond

™

Contact Adhesive

2000NF helps accelerate production

speed of rigid and soft laminations

beyond most water-based and

conventional solvent-based systems.

5

6

7